Technical Expertise and Material Compatibility

Evaluating Supplier Experience with Aluminium Bending Techniques

Suppliers with 10+ years specializing in aluminium bending machines achieve 34% fewer tolerance errors compared to generalist manufacturers (2024 Industrial Machinery Report). Prioritize partners who can demonstrate:

- Mastery of springback compensation strategies for series 5000/6000 alloys

- Experience with asymmetric bending geometries common in aerospace and automotive components

- Validated process control plans for batches exceeding 1,000 units

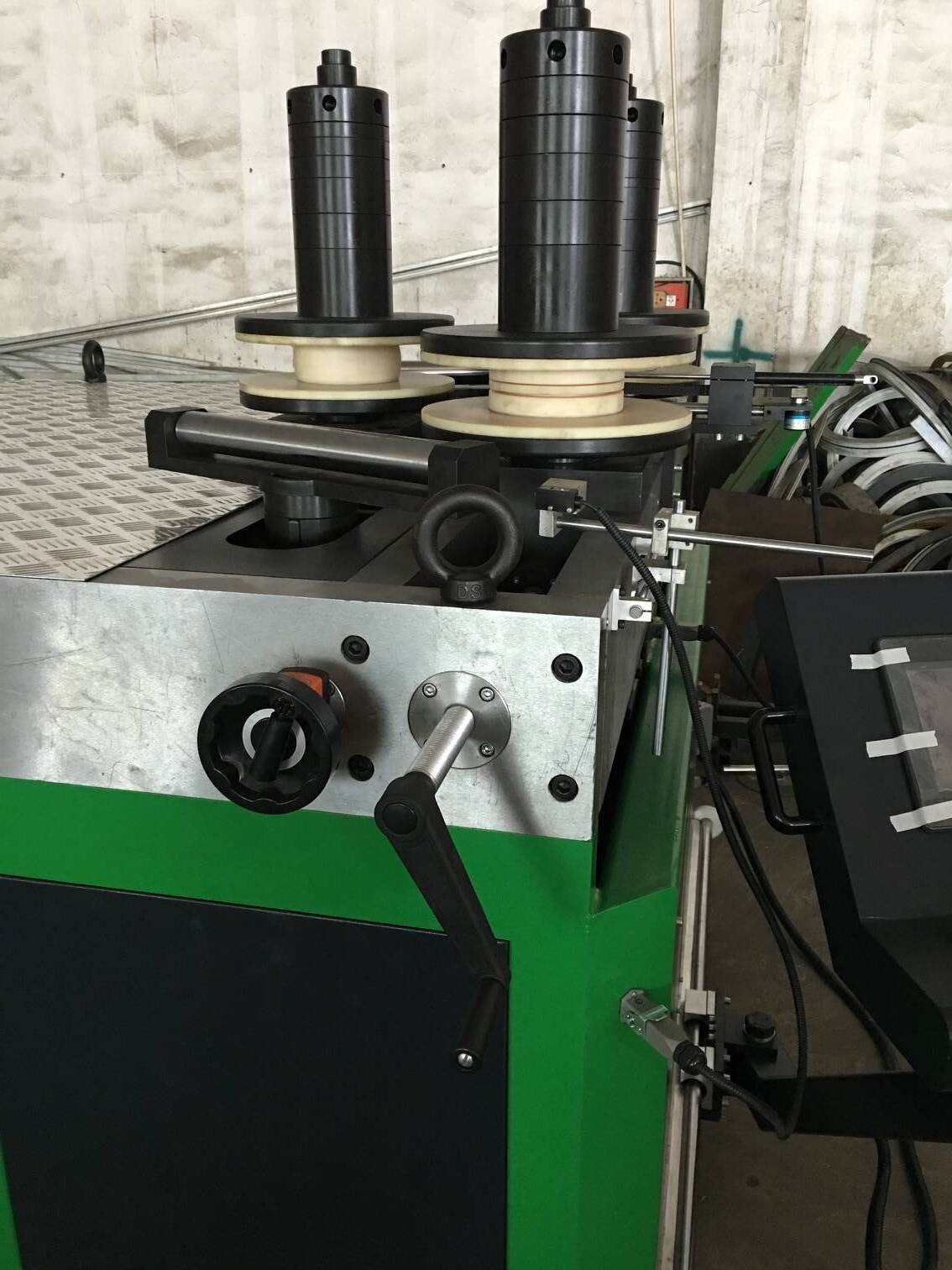

Alloy Compatibility and Its Impact on Machine Performance

Material selection directly influences machine calibration—5083-O aluminium requires 18% lower bending forces than 6061-T6 but demands tighter radius controls to prevent cracking. Leading suppliers use ASTM-verified compatibility matrices to preconfigure:

■ Hydraulic pressure settings (±50 bar precision)

■ Die clearance adjustments (0.05–0.2mm adaptive range)

■ CNC program presets for common alloys

A 2023 automotive case study revealed manufacturers reduced scrap rates by 27% by collaborating with suppliers who pre-tested 15+ material batches before production, demonstrating how technical specialization improves bulk order efficiency.

Balancing Advanced Machinery with Operator Skill

While modern CNC systems enable 0.1° bend accuracy, 62% of quality deviations stem from improper setup (National Metalforming Association). Top suppliers mitigate this through on-site operator certification, AI-assisted setup verification tools, and real-time process monitoring dashboards. Choose partners whose expertise extends beyond equipment to include skill development and adaptive process engineering.

Machine Capacity and CNC Automation for High-Volume Production

Key Specifications: Tonnage, Bending Length, and Throat Depth for Bulk Orders

Industrial aluminium bending machines require precise capacity matching for bulk production. Three metrics dictate throughput:

| Specification | Impact on Production | Minimum Requirement* |

|---|---|---|

| Tonnage | Determines maximum bendable alloy thickness | 300+ tons |

| Bending Length | Controls maximum part size per operation | 6+ meters |

| Throat Depth | Affects clearance for complex geometries | 400+ mm |

*Based on 2024 Fabrication Equipment Survey of 12 automotive tier-1 suppliers

Matching Machine Capacity to Material Thickness and Order Volume

Aluminium grades like 6061-T6 to 7075 demand 18–35% higher tonnage than steel equivalents. For monthly outputs exceeding 50,000 bent components, suppliers with multi-axis CNC press brakes reduce changeover time by 63% compared to manual systems (Sheet Metal Processing Journal 2023).

Role of CNC Control Systems in Ensuring Repeatability and Precision

Modern CNC systems with ±0.01° angular resolution eliminate human error in high-volume cycles. A 2024 Automation Productivity Study found CNC-integrated machines achieve 99.2% dimensional consistency across 10,000+ parts—critical for aerospace and EV battery tray applications.

Integration with Smart Manufacturing: IoT and Automated Bending Cells

Leading suppliers offer IoT-enabled bending cells that reduce setup time by 78% via automated tool change systems. These cells sync with ERP software to adjust production schedules in real time, cutting idle machine hours by 41% annually (Smart Factory Initiative Report 2024).

Quality Assurance, Certifications, and Precision Control

Why ISO 9001, AS9100, and IATF 16949 Matter in Supplier Selection

Companies that get ISO 9001 certification set up quality management systems that have been thoroughly checked and reviewed, which helps cut down on those annoying little inconsistencies in how things are done day to day. When it comes to bending aerospace grade aluminum, getting AS9100 certified means manufacturers must track every piece of material from start to finish and use stats to control their processes. The automotive industry has its own requirements too through IATF 16949, where factories need to build in ways that prevent mistakes before they happen. What all these certifications really do is make sure companies follow much stricter measurement rules than just checking if parts fit properly. This attention to detail makes a big difference when safety is on the line.

CMM and Laser Inspection: Ensuring Dimensional Accuracy in Aluminium Bending

Coordinate Measuring Machines (CMM) paired with 3D laser scanners create a closed-loop feedback system, verifying bend angles within ±0.1° and wall thickness uniformity across batches. This dual method detects micro-voids in heat-treated alloys missed by caliper checks—essential for structural components in transportation and architecture.

Certified vs. Non-Certified Suppliers: Quality Trade-Offs in Cost-Sensitive Markets

Non-certified suppliers may offer lower upfront costs but often deliver inconsistent bend radii and surface finishes. Certified partners offset initial investment through superior tooling longevity—certified press brake dies maintain ±0.05mm repeatability for 3–5 times longer than non-certified alternatives, significantly reducing replacement frequency in high-volume production.

Production Scalability and On-Time Delivery Performance

When selecting an aluminium bending machine supplier for bulk orders, evaluate their ability to scale production while maintaining delivery commitments. Suppliers must demonstrate transparent capacity planning and historical performance data to align with your project timelines.

Assessing supplier capacity and lead times for large-scale aluminium bending orders

Verify potential partners’ maximum monthly output against your volume needs, factoring in machine uptime and maintenance. Leading manufacturers report 12–18% shorter lead times when suppliers maintain 95%+ on-time delivery rates (2024 Manufacturing KPI Benchmark). Request client references from similar-scale projects, especially those involving complex, multi-shift aluminium bending operations.

Mitigating delays: Dual sourcing and buffer scheduling strategies

Implement contingency plans such as qualifying backup suppliers for critical components, reducing single-source dependency by 40%. Buffer scheduling adds 10–15% time cushions to accommodate material variances in aluminium workflows. Proactive manufacturers using these methods experience 63% fewer rush-order premiums, avoiding an average annual cost of $740,000 due to delays (Ponemon 2023).

After-Sales Support and Long-Term Operational Reliability

Minimizing Downtime With Responsive Technical Support and Service Networks

When looking at suppliers, it really pays off to find ones that offer round-the-clock technical support with response times under two hours for serious problems. According to a recent study on fabrication equipment from last year, plants that have their own service teams cut down unexpected downtime by around 60-65% versus facilities that depend on outside contractors. Top manufacturers now equip their machines with IoT technology that actually warns techs when parts start showing signs of wear or when calibration starts drifting off track. This kind of early warning system lets maintenance crews fix things before breakdowns happen, which saves both time and money in the long run.

Evaluating Global Spare Parts Availability and Maintenance Responsiveness

It makes good business sense to check if suppliers keep regional warehouses stocked with around 85% of the parts that get replaced most often, think hydraulic seals or CNC axis drives for instance. Companies lucky enough to have local access to spare parts see repair times drop by about 92% compared to businesses stuck waiting for shipments from across the ocean. Looking ahead, it pays dividends to work with vendors who offer thorough maintenance training sessions tailored specifically to how operators handle bending operations day to day. The savings add up fast too — shops report cutting service expenses between $18k and $25k annually per machine just from better trained staff. Plus machines tend to last anywhere from three to five extra years when operators know exactly what they're doing during routine maintenance checks.

FAQ Section

What are the key factors to consider when selecting an aluminium bending machine supplier?

Key factors include the supplier's technical expertise, experience with specific aluminium alloys, machine capacity, CNC automation features, and quality assurance certifications like ISO 9001, AS9100, or IATF 16949.

Why is certification important for aluminium bending machine suppliers?

Certifications like ISO 9001, AS9100, and IATF 16949 ensure that suppliers adhere to strict quality management systems. They help reduce inconsistencies in production and enhance safety by enforcing rigorous measurement controls.

How can advanced CNC systems benefit aluminium bending processes?

Advanced CNC systems with high angular resolution improve repeatability and precision in bending processes. They eliminate human error in high-volume cycles, ensuring consistent dimensional accuracy.

What strategies can mitigate production delays with aluminium bending orders?

Employ dual sourcing for critical components and use buffer scheduling to accommodate material variances. These strategies can significantly reduce rush-order premiums and improve timely delivery performance.

Table of Contents

- Technical Expertise and Material Compatibility

- Machine Capacity and CNC Automation for High-Volume Production

- Quality Assurance, Certifications, and Precision Control

- Production Scalability and On-Time Delivery Performance

- After-Sales Support and Long-Term Operational Reliability

-

FAQ Section

- What are the key factors to consider when selecting an aluminium bending machine supplier?

- Why is certification important for aluminium bending machine suppliers?

- How can advanced CNC systems benefit aluminium bending processes?

- What strategies can mitigate production delays with aluminium bending orders?