Understanding Aluminum Profile Cutting Machine Types and Key Specifications

Types of aluminum cutting saws: Double mitre, automatic, and tilting models

Aluminum profile cutting equipment today generally comes in three main types. The double mitre saws can handle angled cuts reaching around 200 mm high thanks to their synchronized dual heads, which makes these machines great for working on those complicated architectural shapes. Then there are the automatic versions like CNC controlled systems that achieve pretty impressive accuracy levels, roughly plus or minus 0.1 mm, because they use servo motors along with programmed operations. For curtain walls and similar applications, tilting machines come into play since they allow cuts at angles ranging between about 22 degrees all the way up to nearly 160 degrees. A recent look at industry data from last year showed that switching to automatic saws cuts down on wasted materials by approximately 18 percent when compared against traditional manual methods.

CNC vs. manual aluminum profile cutting machines: Performance and use cases

CNC machines dominate high-volume production environments, achieving 97% first-cut accuracy (Fabrication Tech Journal 2024), while manual models are better suited for small workshops handling fewer than 500 cuts per day. Key differentiators include:

- Throughput: CNC systems process 120 profiles/hour versus 40/hour manually

- Operator dependency: Manual cutting requires 2.7x more skilled labor

- Adaptability: CNC integration allows real-time adjustments for mixed batches

Critical technical specifications influencing machine price and capability

Four specifications account for 78% of machine costs (2024 Machinery Cost Index):

- Motor power: Ranges from 2.2–5.5 kW, directly affecting cutting depth (60–300 mm)

- Blade speed: Minimum 3,400 RPM required for clean aluminum cuts

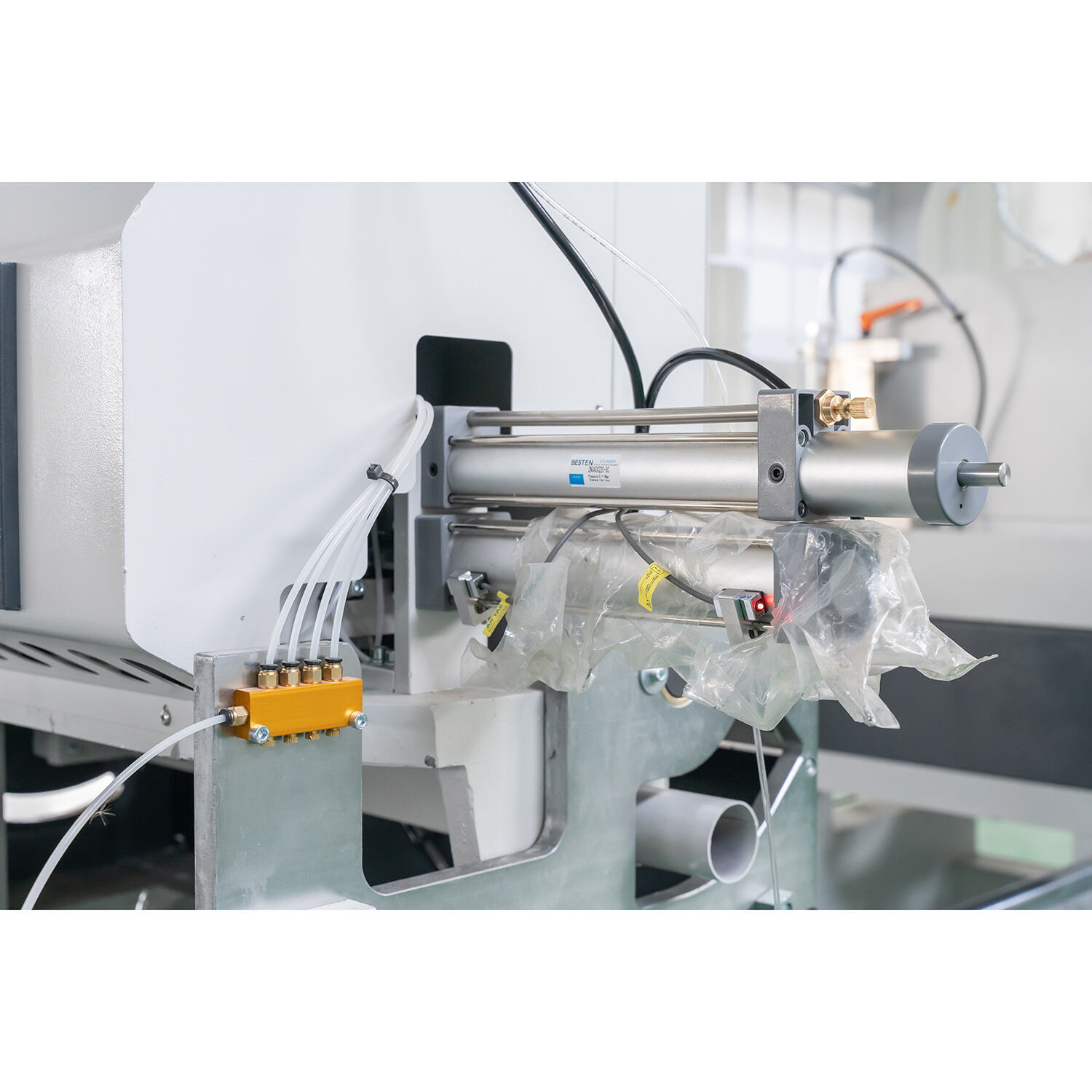

- Clamping force: At least 0.8 MPa to prevent material slippage

- Positioning accuracy: High-end models maintain ±0.05 mm variance

Industrial-grade units typically include IP54-rated dust protection and bearings rated for 50,000 hours, justifying their 40–60% higher cost over entry-level options.

Evaluating Cutting Precision, Build Quality, and Long-Term Durability

Measuring Cutting Precision and Accuracy Across Suppliers

How precise something gets really matters for how well production runs. The best machines out there can hit tolerances around plus or minus 0.1 mm, which is pretty impressive stuff. When running automation setups though, even small errors creep in over time. These little mistakes don't just look bad they actually weaken structures and send scrap rates skyrocketing sometimes by as much as 12%, according to industry data from last year. Want to know if what suppliers promise actually works? Try running some standard tests on those 6000 series aluminum profiles with good quality laser measuring equipment. That hands on approach tells the real story behind all those specs and promises.

Key Factors Affecting Cut Quality: Blade Type, Alignment, and Vibration Control

Cut consistency depends on three core elements:

- Blade type: Carbide-tipped blades last 40% longer than steel variants and maintain edge runout below 0.005 mm

- Alignment: Dual-axis laser systems reduce angular deviation by 90% compared to manual calibration

- Vibration control: Dynamic counterbalance mechanisms limit harmonic resonance to under 2 µm, crucial for thin-wall profiles

Proper blade geometry selection improves surface finish quality by 35% in aerospace-grade aluminum applications.

Material Construction and Build Quality: What Defines a Premium Machine

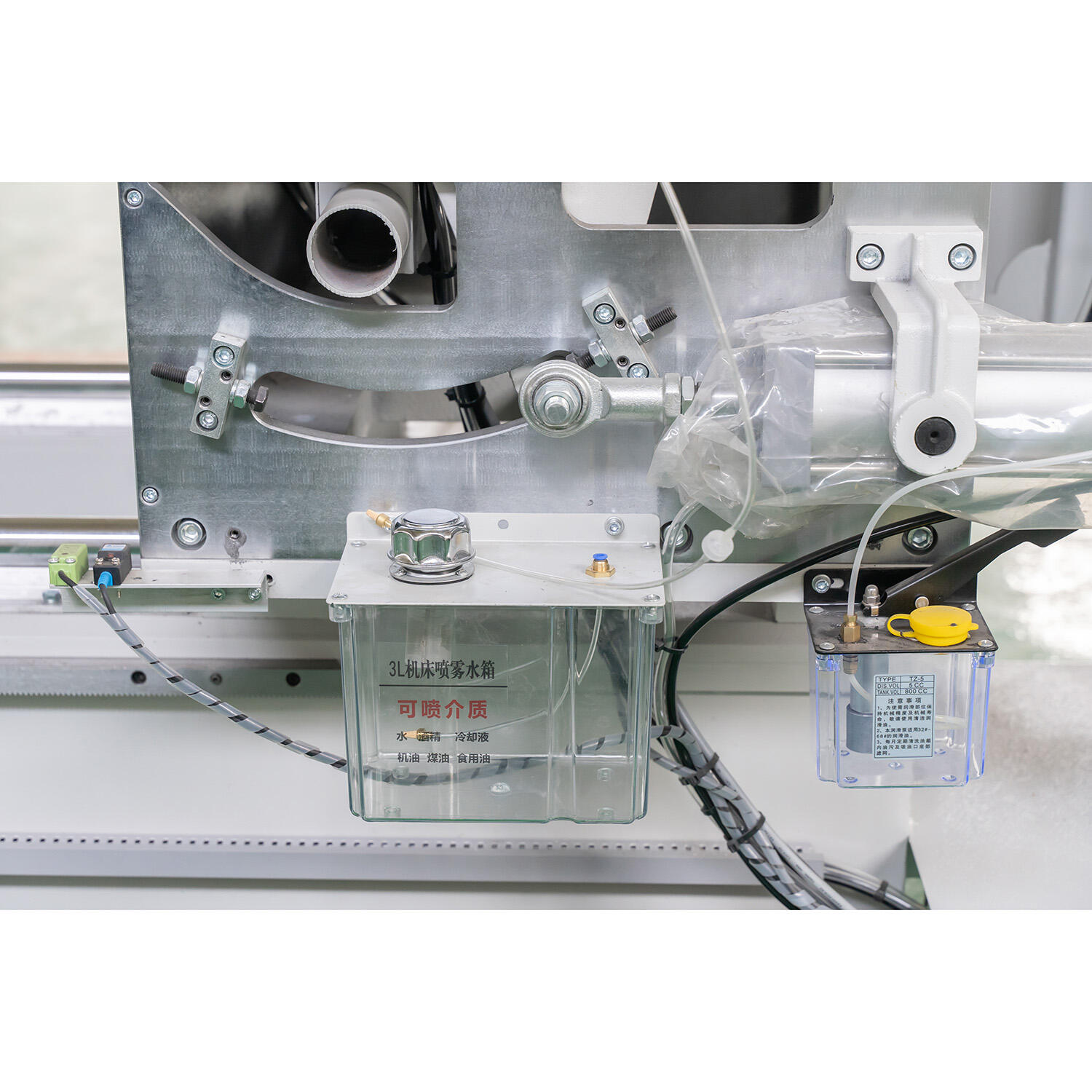

Premium machines feature welded 20-mm steel frames and cast iron guide rails, maintaining positional accuracy below 0.01 mm/m under load. Leading builders use ISO-classified bearings and IP67-rated components resistant to corrosion from prolonged coolant exposure.

Durability Benchmarks and Reliability Data (2020–2023 Industry Insights)

Analysis of over 850 facilities shows that machines equipped with automated lubrication systems experience 60% fewer spindle failures within 50,000 operating hours. Units with hardened steel gears (HRC 58–62) last three times longer than those with carburized gears in high-cycle aluminum cutting operations.

Assessing Automation Levels and Their Impact on Productivity and ROI

From Semi-Automatic to Full CNC Integration: Automation Tiers Explained

Aluminum profile cutting machines operate across three automation tiers:

| Automation Tier | Labor Input | Key Features | Typical ROI Timeline |

|---|---|---|---|

| Semi-Automatic | High | Basic blade control | 12–18 months |

| Automatic | Moderate | Automated material handling | 8–12 months |

| Full CNC Integration | Minimal | Programmable precision cutting | 6–9 months |

Semi-automatic systems require constant operator input for positioning, whereas full CNC models execute pre-programmed cutting paths at ±0.1 mm accuracy. Advanced CNC controllers now incorporate vibration-dampening technology to sustain precision at speeds exceeding 120 m/min.

How Automation Reduces Labor Costs and Increases Production Throughput

Automated systems reduce manual labor needs by 30–50% and boost throughput by 20–110%, according to a 2023 industry analysis. This performance gain stems from:

- Continuous operation without fatigue-related errors

- 35–70% faster tool changeovers via automatic blade positioning

- 99.2% material utilization through optimized nesting algorithms

Integrated chip evacuation systems further reduce downtime, enabling some operations to run 22-hour cycles with only one or two personnel.

Case Study: ROI Improvement with Automated Aluminum Profile Cutting Systems

A Midwest metal fabricator upgraded to CNC-integrated cutting machines in 2021, achieving:

- 40% productivity gain within six months

- 25% reduction in labor costs ($142k annual savings)

- ROI in 9.3 months through holistic cost-benefit analysis

The upgrade eliminated $78k/year in material waste caused by manual measurement errors, while predictive maintenance sensors extended blade life by 27%. These outcomes align with 2024 AMT data showing manufacturers with full CNC automation achieve 18–34% faster ROI than those using semi-automatic systems.

Comparing Supplier Support: Warranty, Service, and Spare Parts Accessibility

Warranty Terms as Indicators of Supplier Confidence and Machine Quality

Top manufacturers offer warranties of three or more years on industrial-grade equipment, reflecting confidence in durability. Extended coverage correlates with 23% fewer component failures in CNC systems (2023 reliability benchmarks). Buyers should carefully review exclusions for wear items like blades and rails to avoid unexpected repair costs.

Technical Support Responsiveness and Expertise Across Leading Suppliers

Suppliers offering 24/7 technical support with video diagnostics resolve issues 32% faster (2022 Productivity Survey). Prioritize vendors with certified technicians trained on your specific control interface, especially for automated systems requiring specialized maintenance.

Spare Parts Availability and the Risk of Service Gaps

A 2023 ScienceDirect study found that 68% of production stoppages result from delayed delivery of critical components such as hydraulic clamps or servo motors. Ensure suppliers maintain regional warehouses stocking:

- Cutting blades (TCT and carbide-tipped variants)

- Guide rail assemblies

- Motorized feed system gearboxes

Facilities using suppliers with ±48-hour spare parts delivery reduced unplanned downtime by 41% compared to those relying on overseas shipments. Manufacturers providing machine-specific compatibility charts and lifecycle cost calculators empower buyers to make informed procurement decisions.

Analyzing Total Cost of Ownership vs. Upfront Price in Machine Procurement

Total Cost of Ownership (TCO) and Return on Investment (ROI) Framework

Most buyers get caught up looking at what something costs when they first see it, completely missing out on all those hidden expenses down the road. When we look at total cost of ownership, things start to change perspective pretty quickly. Maintenance alone eats up around 30 to 40 percent of the budget, followed by energy costs somewhere between 15 and 20 percent, plus blade replacements taking another 10 to 15 percent. These numbers add up way beyond just the original purchase price after about five years in operation. Looking at return on investment makes sense here too. The math works out where machines that might cost 15 to 20 percent more initially can actually give back 35 to 50 percent better returns because they break down less often and need servicing far less frequently according to the Industrial Machinery Report from last year.

Operating and Maintenance Costs Over a 5-Year Lifecycle

Entry-level saws averaging $45k upfront incur $28k in maintenance, while premium $85k models require only $12k—a 57% difference in lifecycle costs. Major cost drivers include:

- Blade replacement frequency (every 8k cuts vs. 25k cuts for hardened steel models)

- Coolant system efficiency (30–50% variation between brands)

- Spindle rebuild costs ($2.5k per incident, averaging 18 hours of downtime)

Price-to-Performance Comparison: Entry-Level vs. Industrial-Grade Machines

While budget models handle 120 profiles/hour with ±0.5mm precision, industrial CNC systems process over 400 profiles/hour at ±0.05mm—essential for aerospace and automotive applications. Entry-level machines generate $0.18/cut in material waste, whereas precision-ground industrial blades reduce this to $0.07 through optimized kerf and alignment.

Hidden Costs and Upgrade Paths in Aluminum Profile Cutting Machine Sourcing

First time buyers often run into unexpected costs when setting up shop. Factory floor changes typically set them back around $15,000 on average, while training each worker adds another $5,000 to the bill. About seven out of ten new owners face these surprises. Going modular makes a big difference though. Machines built with internet connectivity save businesses about 60 percent in potential upgrade expenses down the road compared to traditional fixed systems. Many smart suppliers now have retrofit options too. For example, turning old manual saws into semi automatic ones pays for itself roughly 40 percent quicker than buying brand new equipment altogether. This approach helps companies stretch their budgets further without sacrificing efficiency.

FAQ Section

What are the main types of aluminum profile cutting machines?

The main types of aluminum profile cutting machines are double mitre saws, automatic CNC systems, and tilting models, each designed for specific cutting applications and accuracy.

How does CNC automation benefit aluminum cutting?

CNC automation allows for high-volume production with outstanding first-cut accuracy, reducing manual labor, and enabling real-time adjustments for mixed batches.

What factors influence the cost of aluminum cutting machines?

Key specifications that influence machine costs include motor power, blade speed, clamping force, and positioning accuracy.

Why is it important to consider the total cost of ownership rather than just the upfront price?

Considering the total cost of ownership helps you understand hidden costs such as maintenance, energy, and blade replacements over time.

What are the benefits of automating aluminum profile cutting?

Automation reduces labor costs, increases production throughput, minimizes fatigue errors, and optimizes material utilization.

Table of Contents

- Understanding Aluminum Profile Cutting Machine Types and Key Specifications

- Evaluating Cutting Precision, Build Quality, and Long-Term Durability

- Assessing Automation Levels and Their Impact on Productivity and ROI

- Comparing Supplier Support: Warranty, Service, and Spare Parts Accessibility

- Analyzing Total Cost of Ownership vs. Upfront Price in Machine Procurement

- FAQ Section

- How does CNC automation benefit aluminum cutting?