Understanding PVC Profile Cutting Machine Mechanics

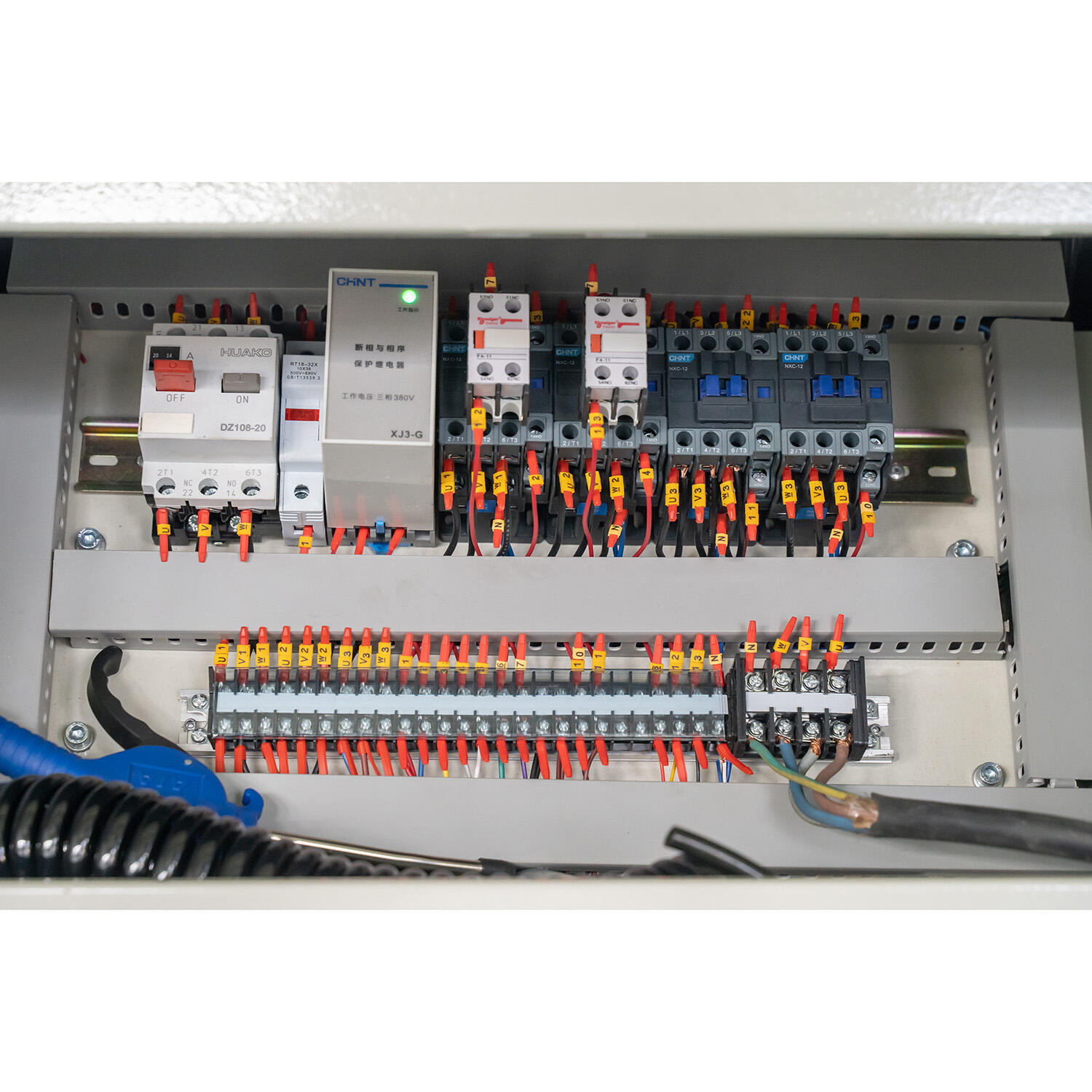

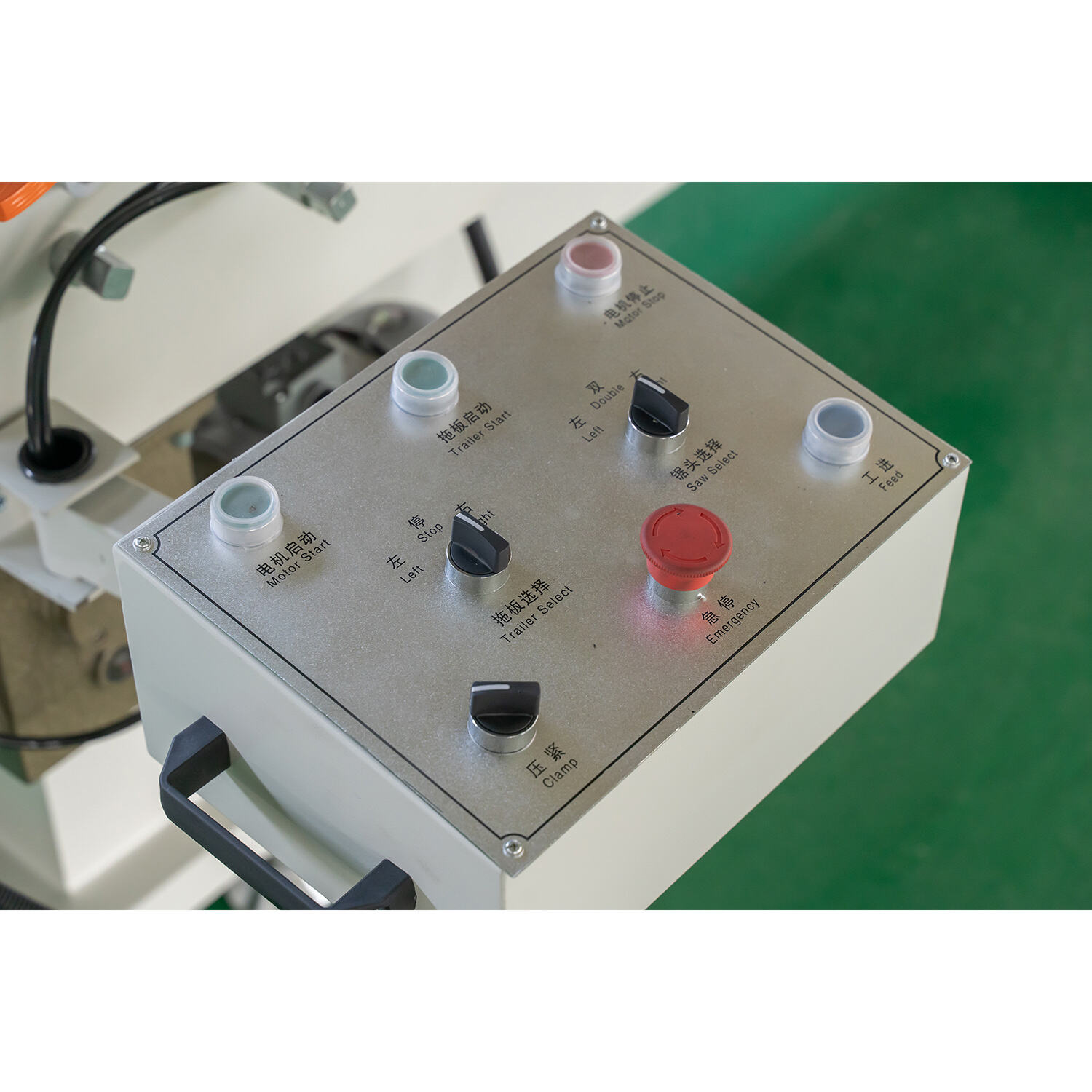

Understanding the mechanics of PVC profile cutting machines involves examining their key components, such as the cutting blade, motor, and frame. Each component is integral to the machine's operation:

- Cutting Blade: The blade is crucial for precise cutting; its sharpness and durability directly impact the end product's quality. Regular maintenance is essential to keep it in optimal condition.

- Motor: The motor powers the entire system, ensuring that the blade operates efficiently. Its performance influences the machine's speed and accuracy, pivotal for high productivity.

- Frame: The frame provides stability, minimizing vibrations that could compromise precision. It's important for maintaining accuracy throughout the cutting process.

These components must be regularly maintained to extend their lifespan, typically lasting several years with proper care, boosting both efficiency and precision in the cutting process.

Role of CNC Technology in Precision Cutting

CNC technology plays a transformative role in enhancing precision cutting in PVC profile cutting machines. By automating the cutting process, CNC greatly reduces human errors associated with manual operations. Implementing CNC technology in PVC cutting machines parallels its adaptation in aluminum profile cutting machines:

- Increased Accuracy: CNC systems ensure unparalleled precision by following exact programmed paths, leading to consistent cuts.

- Reduced Waste: The precision offered by CNC technology means less material wastage, which saves costs and resources.

- Operational Efficiency: Statistics point to an increase in operational efficiency by up to 40% when CNC technology is utilized, compared to traditional methods.

This advancement showcases how embracing technology can significantly improve production processes, leading to better product quality and heightened competitive advantage.

Differences Between PVC and Aluminum Profile Machines

Understanding the distinct differences between PVC and aluminum profile cutting machines is crucial for selecting the right equipment. These differences arise from the variations in cutting processes and machine setups:

- Material Properties: PVC is lightweight and flexible, while aluminum is rigid and heavier. This affects machine design; for instance, PVC machines prioritize flexibility, whereas aluminum machines focus on strength and stability.

- Cutting Blades: Blades for PVC are generally less fortified than those for aluminum, due to PVC's softness compared to aluminum's hardness.

- Speed and Precision: PVC machines often operate at higher speeds due to the material's lightweight nature but require frequent precision checks to ensure cutting quality.

Manufacturer guidelines and technical resources provide evidence of these differences, emphasizing the importance of selecting machines tailored to specific material needs for optimum performance and efficiency.## Essential Maintenance for Peak Performance

Blade Sharpness & Alignment Checks

Keeping cutting blades sharp and properly aligned makes all the difference when it comes to achieving good cut quality and getting maximum performance out of machines during PVC profile cutting operations. Most operators find that checking blade sharpness around every 50 hours works well to catch those dull spots before they start producing rough cuts that nobody wants to deal with later. The manufacturer usually provides some basic guidance on how to check alignment, something worth following closely because even slight misalignments will result in those frustratingly uneven cuts across profiles. Many experienced technicians actually suggest double-checking blade alignment right after installing a fresh blade too. This extra step helps avoid unnecessary stress on the machine components and saves time down the road when unexpected breakdowns could really disrupt production schedules.

Lubrication and Dust Removal Strategies

Getting the right amount of lubricant on those PVC welding machines makes all the difference when it comes to keeping them running smoothly and avoiding unnecessary wear and tear over time. Most manufacturers recommend greasing parts about once a month, though some manuals might suggest different intervals depending on usage conditions. Dust buildup is another big concern for these machines since particles get everywhere and mess with their performance. Regular cleaning matters a lot here. A good vacuum with HEPA filtration works wonders, or sometimes people use compressed air to blow out stubborn debris. Industry pros generally agree that finishing up with a quick dust clean at the end of each workday keeps everything operating at its best without surprises down the road.

Calibrating Feed Rate Sensors

Getting feed rate sensors properly calibrated makes all the difference when it comes to consistent cut quality and keeping those CNC aluminum cutting machines running at peak performance. The process isn't complicated if done right. Start by finding the right calibration tools for the job, then tweak those sensors according to what the manual says. After adjustments, run some test cuts to check how accurate everything really is. When shops stick to regular calibration schedules, they tend to see much better results from their manufacturing processes. Less wasted material and tighter tolerances become standard rather than exceptions. Industry data shows something pretty compelling too. Shops that make sensor calibration part of their routine maintenance typically boost operational efficiency by around 20%. That kind of improvement adds up fast across production runs, making good calibration practices well worth the time investment.

Balancing Speed vs. Cut Quality

Getting the right mix between how fast we cut and the quality of those cuts matters a lot for getting the best out of PVC processing machines. When operators tweak the cutting speed, they直接影响 the final product quality too. Push things too fast and we end up with rough edges and less precise cuts. Many shops actually slow things down when dealing with thicker materials or tougher stuff just to get a nicer finish. Material matters big time here. Thicker or harder plastics need slower speeds, while softer ones can handle going quicker without sacrificing quality. One shop nearby saw real improvements after adjusting their machine settings based on different material types. They spent some time testing various speeds until they found what worked best for each job.

Material Thickness and Blade Selection

When working with PVC profiles, their thickness really makes a difference in what kind of blade should be used during cutting operations. Getting good results means finding the right blade for the job based on how thick the material actually is. Take it this way: thin blades work okay enough for light duty stuff, but when dealing with heavy duty profiles that pack more density, nothing beats those sturdy thick blades that get the job done without breaking a sweat. Most seasoned professionals will tell anyone who asks about their shop practices that investing in blades made specifically for certain tasks leads to much cleaner edges on finished products. Anyone who has tried swapping out general purpose blades for ones tailored to particular profile thicknesses knows firsthand how much better cuts turn out and how little waste ends up accumulating over time. The bottom line remains simple though complicated sounding stuff aside – pick the wrong blade and everyone pays the price later.

Temperature Control for Clean Edges

Getting the temperature right makes all the difference when it comes to clean cuts without melting the material. When operators keep temperatures under control, they end up with those nice smooth edges everyone wants. Most shops know that staying within certain temperature ranges stops materials from getting too hot and ruining the final product. People who work with PVC cutting day in and day out will tell anyone who asks about the problems that come from poor heat management. They see firsthand how good temperature control leads to better looking products and less waste from burned or warped sections. For anyone serious about quality PVC work, mastering temperature control isn't just important it's absolutely essential for making sure every cut meets standards.

Ventilation for Fume Management

Good ventilation is really important when working with PVC materials because it helps get rid of those nasty fumes that can build up during processing. Without proper airflow, workers breathe in all sorts of bad stuff like VOCs and other dangerous chemicals that hang around in the workshop. Safety agencies like OSHA have strict rules about how clean the air needs to be in factories, which means businesses must invest in decent ventilation if they want to stay compliant. Companies that actually follow through on these requirements see real benefits. Take the plastics manufacturing plant down the road from me - since they installed better exhaust systems last year, their sick days related to breathing problems dropped by almost half. Makes sense really, because nobody wants to cough themselves into early retirement just doing their job.

Fire Prevention with Flammable Materials

When working with PVC, which catches fire pretty easily, having good fire safety procedures in place matters a lot. Getting the right equipment makes all the difference in preventing fires while doing cutting work. Fire resistant curtains around the workspace and those automatic shut off switches really help stop accidents before they happen. Looking at what happens in factories where people process PVC shows us that bad fire management leads to serious problems most of the time. We've seen injuries occur and expensive equipment destroyed because someone didn't follow basic safety rules. From experience, we know that being ready for emergencies and following those safety instructions isn't optional it's absolutely necessary for anyone dealing with this material regularly.

Protective Gear Requirements

Getting workers to put on their necessary safety gear when cutting PVC remains a top concern for keeping workplaces safe. The right personal protective equipment, including thick gloves, eye protection, and face shields, acts as a shield between employees and dangerous flying debris. Most shops have rules requiring this stuff anyway, so compliance isn't optional for anyone working near those machines. Safety professionals often stress that companies should regularly check if their current gear meets modern standards, since new materials keep coming out that offer better protection than older versions did. While buying quality protective equipment definitely helps meet legal obligations, many plant managers find that well-equipped workers tend to feel more secure on the job, which translates into fewer accidents and generally happier staff members over time.

PVC vs. Aluminum Cutting Machine Workflows

Cutting processes for PVC are quite different from what we see with aluminum because these materials just don't behave the same way. PVC is basically a thermoplastic, so it bends more easily but needs careful temperature management during cutting to avoid melting into something unrecognizable. Aluminum on the other hand is harder stuff altogether, and when heated improperly tends to warp all over the place. For PVC work, most shops run their cutting equipment at lower temps and adjust speed settings since this material isn't as tough as metal. When working with aluminum though, many manufacturers rely heavily on CNC machines equipped with specialized bits to handle the stiffness and produce clean edges without chipping. Looking at how long things take, there's actually research showing that setting up for PVC cuts takes less time overall compared to aluminum jobs which require extra steps before and after cutting, including thorough cleanup procedures that nobody really enjoys doing.

Advantages Over Laser and Plasma Systems

Looking at PVC cutting tech against laser and plasma options reveals some real advantages worth considering. Cost matters a lot here. Unlike lasers and plasma cutters which guzzle power and demand constant maintenance, PVC cutters keep things simple on the wallet front. These machines work great for all sorts of jobs from building sites to pipe installations without needing those fancy safety precautions that come standard with high energy equipment. Real world tests back this up too. When working with non conductive stuff like PVC pipes specifically, these cutting tools make life easier for operators while cutting down on risks posed by intense heat systems. Many workshops have switched over just because their budgets couldn't handle the ongoing expenses of maintaining laser or plasma setups.

Integration with Welding and Bending Equipment

When manufacturers combine PVC cutting machines with welding and bending equipment, they get production environments where everything flows together smoothly, which makes operations run better and produces higher quality products. The real benefit comes from how these integrated systems cut down on the time workers spend moving materials around between different stations, and that translates into real savings on the bottom line. Many businesses in the manufacturing sector are now going this route because they want faster production without sacrificing accuracy or worker safety throughout all those cutting, welding, and bending steps. Take for example a few companies in Germany who recently installed these kinds of combined systems. Their PVC cutting gets automatically fed into the welding station right after being cut, then moves directly to the bending process. What happens? Throughput goes up significantly while product consistency remains rock solid across entire production runs.

Table of Contents

- Understanding PVC Profile Cutting Machine Mechanics

- Role of CNC Technology in Precision Cutting

-

Differences Between PVC and Aluminum Profile Machines

- Blade Sharpness & Alignment Checks

- Lubrication and Dust Removal Strategies

- Calibrating Feed Rate Sensors

- Balancing Speed vs. Cut Quality

- Material Thickness and Blade Selection

- Temperature Control for Clean Edges

- Ventilation for Fume Management

- Fire Prevention with Flammable Materials

- Protective Gear Requirements

- PVC vs. Aluminum Cutting Machine Workflows

- Advantages Over Laser and Plasma Systems

- Integration with Welding and Bending Equipment