Precision and Cutting Accuracy Standards

Role of Blade Quality in Aluminum Profile Cutting

When it comes to cutting aluminum profiles, blade quality makes all the difference in getting clean, precise results. Better blades just don't wear out as fast and they leave much smoother edges on the material being cut, which means work gets done faster without constant interruptions. Take carbide coated blades or those made from high speed steel for example these last significantly longer before needing replacement and need far less upkeep during regular shop operations. Industry insiders point out that spending money upfront on good quality blades actually saves cash in the long run because there's less scrap material wasted and finished products look better too. Plus machines stay running longer without unexpected breakdowns. For shops serious about maintaining top notch standards in their aluminum profile work, this connection between blade choice and overall productivity simply cannot be ignored.

Calibration Systems for CNC Metal Cutting Machines

Getting CNC metal cutting machines properly calibrated matters a lot for keeping things accurate, particularly when running at full speed in mass production settings. How precise those cuts end up depends pretty much on if someone does it by hand or lets the system handle it automatically. There are all sorts of calibration options out there these days, from fully automated setups to good old fashioned manual adjustments, and they really do make a difference in how well the cutting actually works. When shops stick to regular calibration routines, they see better machine performance overall while wearing down components less quickly. Machines stay sharp longer too, which means fewer headaches with replacements. Shops that keep their calibration game strong report cleaner cuts day after day, plus their equipment lasts years longer than those who skip regular checks. The bottom line? Proper calibration pays off big time in terms of what gets produced and how much money stays in the bank over time.

Material Compatibility and Cutting Capacity

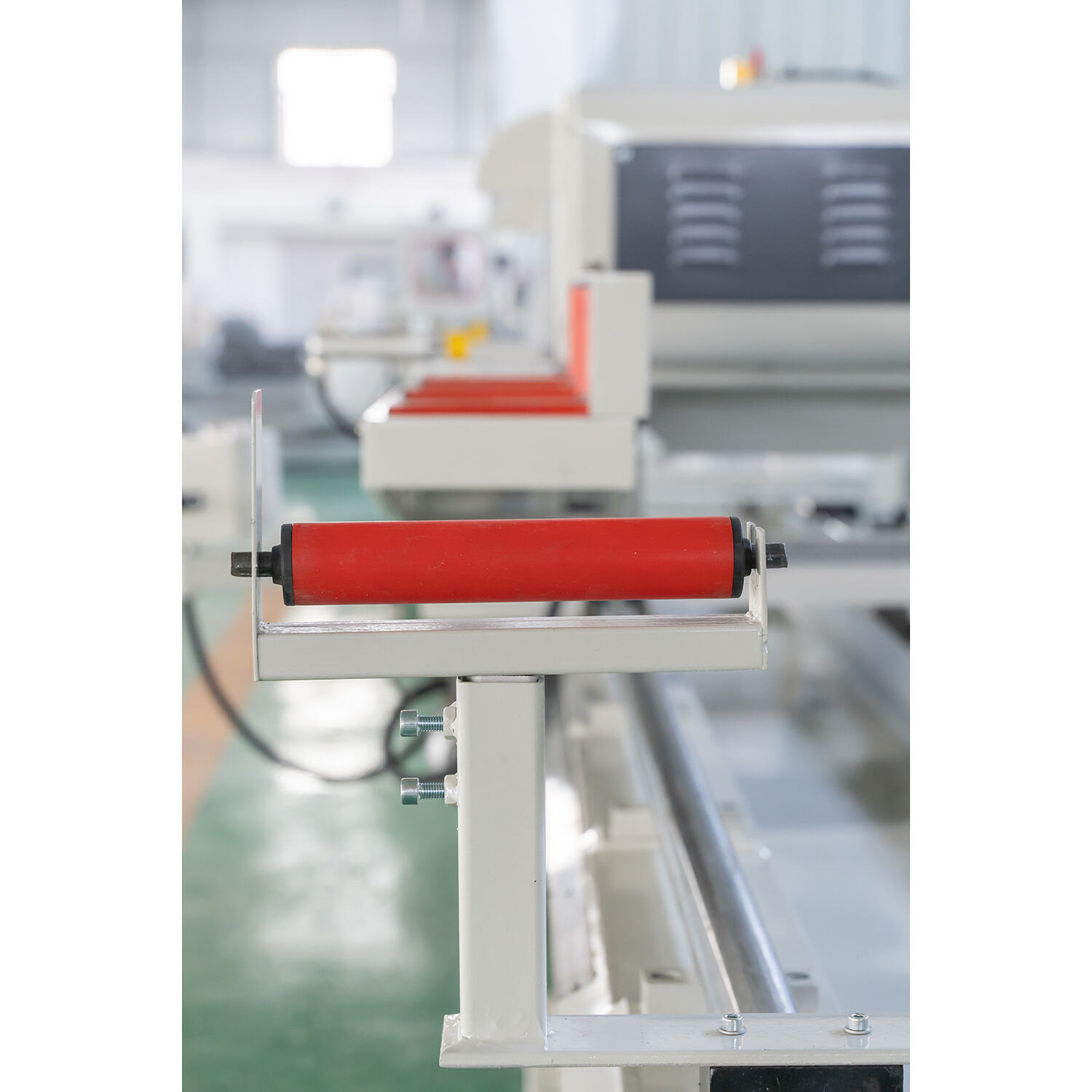

Handling Diverse Aluminum Profiles Extrusion Equipment

CNC machines need real versatility to handle all sorts of aluminum profiles, from basic shapes to those custom designs that push manufacturing boundaries. When working with these machines, adapting to varying specs ensures proper cutting results across different jobs. Material compatibility matters a lot too, especially with various alloys used in extrusion processes. This compatibility affects both how much product gets made (yield rates) and how long it takes to produce. Manufacturers looking at their options should focus on CNC systems capable of handling diverse materials while still delivering good performance. Looking at what's happening in the industry lately, better material compatibility means fewer headaches during production runs and improved efficiency overall. With aluminum profiles getting increasingly complex and varied, being able to switch between materials without major adjustments has become practically mandatory for most manufacturers trying to stay competitive.

Sheet Metal Profile Machine Integration Considerations

Sheet metal profile machines need to fit well into current workflows if we want better operational efficiency. When these machines integrate smoothly with what's already happening on the shop floor, production gets faster and cleaner, which means more parts coming out per hour. Knowing exactly what each machine can do matters a lot when picking equipment for different jobs. A laser cutting machine won't work as well for stamping operations, after all. Getting the right match between machine and task leads to real gains in productivity while saving money over time. Factory stats show that proper integration often boosts output by around 15-20%, depending on how well everything works together. Smart planning about where to place and connect these machines makes a big difference in day-to-day operations. Manufacturers who take this seriously see fewer bottlenecks and less wasted time waiting for one process to finish before another can start.

Automation and CNC Technology Integration

CNC Metal Cutting Machine Programming Flexibility

The flexibility built into CNC programming makes all the difference when working on complicated metal cuts without having to constantly reconfigure equipment. Machines equipped with adaptable programming can handle a wide range of different profile sizes and shapes, which really boosts how fast things get done. Most shops rely on standard programming languages like G-code and M-code for their day-to-day work. These code systems give operators solid control over cutting processes, letting them get those exact results they're after. Take a shop that specializes in detailed metal parts for example. When they switched to more flexible CNC programming, setup time dropped dramatically and there was far less need for people to tweak things manually during production runs. The bottom line? Manufacturers report noticeable improvements in how much they produce and how accurate those products end up being across multiple production cycles.

Aluminium Guillotine Shearing vs. Foil Die Cutting Methods

Comparing aluminium guillotine shearing against foil die cutting reveals big differences in how efficient each method is and what kinds of jobs they work best for. Guillotine shearers are fast machines that handle straight cuts really well, which makes them great for things like sheet metal trimming or panel cutting. Foil die cutting on the other hand shines when working on complicated shapes and fine details, think about those fancy logos or decorative patterns we see in packaging materials. The cost equation looks different too. Guillotine setups take little time to prepare and waste less material during operation, so companies save money there. But when precision matters most, like creating medical device components or aerospace parts, the extra expense of foil die cutting becomes worth it. Most manufacturers stick with guillotines for bulk orders where speed counts, while saving their foil cutters for niche applications where getting every measurement right is absolutely critical. Getting this balance right between both methods helps shops maximize their output without wasting resources unnecessarily.

Safety Features and Operational Efficiency

Emergency Stop Mechanisms for Aluminum Cutting Saws

The emergency stop system is really important for keeping workers safe when cutting aluminum. If something goes wrong, these stops let people shut down the saw right away, which cuts down on accident risks significantly. Most machines come equipped with either push button or pull cord systems. These devices need to pass strict safety tests before installation, so they work fast and dependable when needed most. Some shops even install multiple stopping points along the machine frame just to be extra cautious about worker protection during high speed operations.

Occupational safety data shows that machines with good emergency stop systems cut down on workplace accidents quite a bit. According to recent studies from the Occupational Safety Journal published last year, workplaces that install these safety mechanisms see accident rates drop around 30%. Makes sense really when we think about it. Putting proper safety features into place during machining operations isn't just about following regulations anymore. It actually works to keep employees safe while making the whole work environment much safer for everyone involved.

Ergonomic Design in High-Volume Production Environments

In high-volume production environments, ergonomic design is crucial to minimizing operator fatigue and boosting productivity. By incorporating key elements like adjustable workstations and user-friendly interfaces, machinery can significantly enhance operator comfort and efficiency. Such designs support a more natural posture, reducing the strain on workers engaged in repetitive tasks.

Studies back up what many workers already know about ergonomics. Machines designed with proper ergonomics have been shown to cut down workplace injuries by around 20% according to research published in the Applied Ergonomics Journal last year. When workplaces focus on ergonomics, employees tend to be happier at their jobs too. Plus, there's often a noticeable boost in productivity levels and fewer defects in finished products. Companies that spend money on better designed tools and equipment typically see real results. Workers stay healthier, take fewer sick days, and generally get more done without feeling as tired or stressed out by the end of their shifts. The long term savings from these changes usually far outweigh the initial investment costs.