Түсіну Бұрышты қысу машинасы Негізгі қағидалар

Қазіргі кримп машиналарының негізгі бөліктері

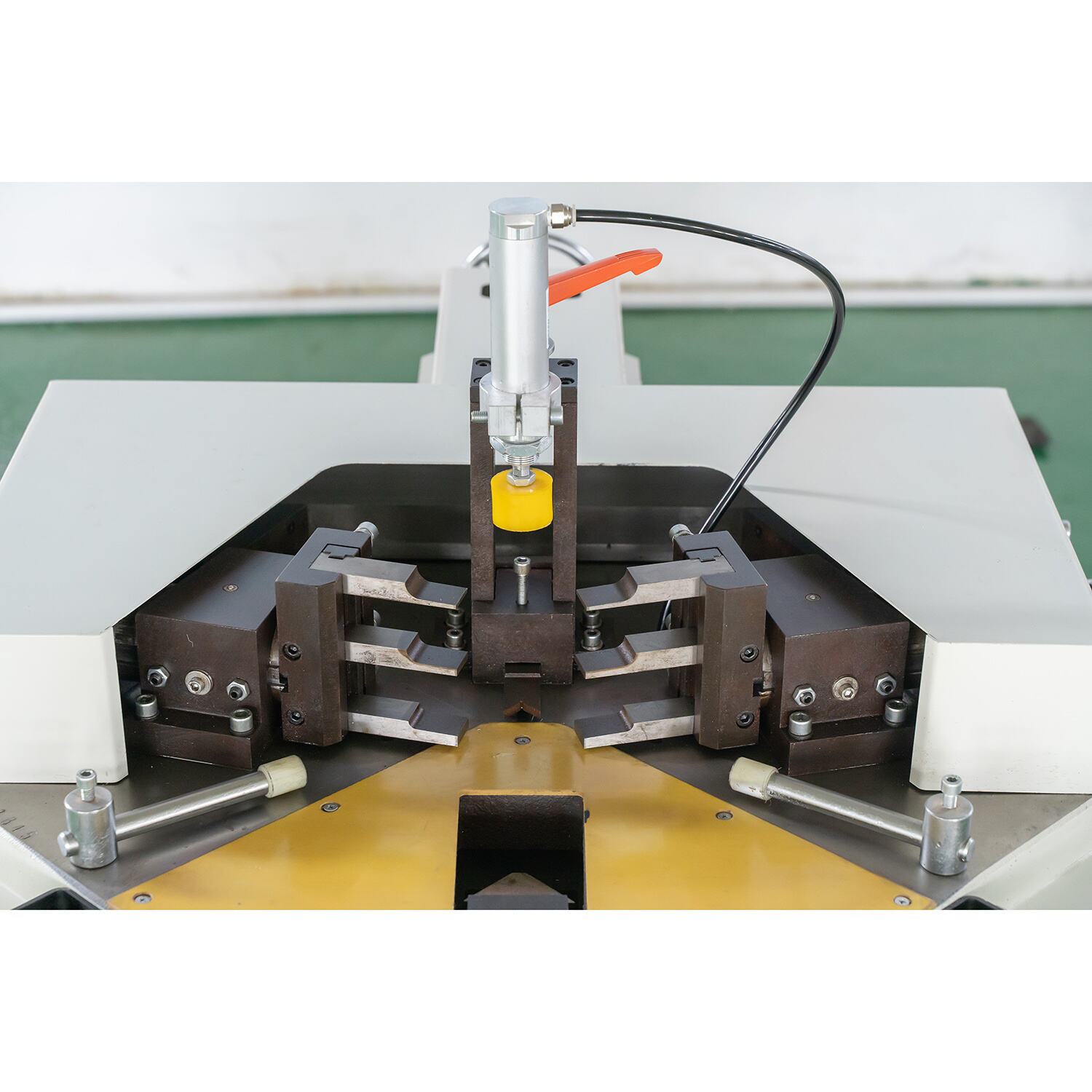

Бұрышты сығу машиналарының әртүрлі компоненттерден тұратын күрделі машиналар, олар нақты амалдар орындайды. Кримптеу басының рөлі зор, себебі ол материалдарды бекіту үшін күш жұмсайды. Жоғары созылуға төзімді болаттан жасалған рама машина пайдаланылған кезде беріктік пен тұрақтылықты қамтамасыз етеді және ол рамасыз немесе рамалы болуы мүмкін. Нақты кримптеу нәтижесі үшін материалдарды қажетті позицияға дәл әкелетін дәл қоректендіру жүйесі маңызды. Осы компоненттерді өндіру үшін материалдарды таңдау — қатайтылған болат сияқты мықты материалдарды таңдау — беріктік пен өнімділік үшін маңызды. Сонымен қатар, гидравликалық және пневматикалық жүйелер кримптеу үшін қажетті үлкен күшті қамтамасыз етеді. Бұл жүйелер әртүрлі өнеркәсіптік қолданыстарда сапалы нәтиже алу үшін тегіс және қуатты қозғалысты қамтамасыз етеді.

Кримп және алюминий қисырту машиналарындағы айырмашылықтар

Құрғау машиналары мен алюминий қабырғаларын бұрғаушы машиналарды салыстыру. Бірінші қарағанда, құрғау машиналары мен алюминий қабырғаларын бұрғаушы машиналар бір-біріне ұқсас көрінсе де, олардың маңызды айырмашылықтары бар. Құрғау машиналары қабырғаларды бірге қосу үшін пайдаланылады, ал алюминий қабырғаларын бұрғаушы машиналар тек бұру үшін, емес же қосу үшін пайдаланылады. Материалдың өзгертілуіne сенімді тәсілдерге салыстырғанда, құрғау басқарымдарының бір бөлігі болып табылады, ал бұрғаушы машиналар әдетте түсіндірілген жұмыстар үшін пайдаланылады. Автомобилдік және ұшу қозғалысы салалары құрғаудың жоғары сапалы қосындылар жасауы мен отбасын азайтуы үшін тиімділігіне себепті. Әрекеттердің шығармашылары құрғаудың бұрғаудан аспапты цикл уақытын азайтуына сенімді деген сөздерімен белгілейді. Жоғары сапалы қосындылар жасалуы мен отбасы материалды азайту – бұл құрғаудың салаларда тиімді тәсіл ретінде қолданылатын себептерінің бірі, мұндағы дәлдік пен тезлік маңызды.

Қосудың Эффективтілігін Өңдеу Шығындары

Тез Қызмет Ету үшін Автоматтық Пікірлеу Системалары

Автоматтық беру жүйесімен кримп машиналарында циклдар арасындағы уақыт салынушылығы өте азайтынды, бұл жеңілсіз қысқа цикл уақытына көмектеседі. Жаңа технологияға сай автоматтандыру арқылы беру процесіне қол жеткізу арқылы өндірістіктерге әрекеттік потоқ беріледі, производительность максималаштырылады және эксплуатация құрметтері төмендегенеді. Мисалы, кримп машиналарына робот қолдарын қосудың мүмкіндігін пайдаланған өnderiстер кеңестердің көмегімен өңдеу процесінің қажеттілігін азайтуға және өндірістікке дейінгі қауіпсіздік пен достыққа қолдау береді. Бұл автоматтандырушы процеске өтілген - бұл операция уақытын оптималаштырудың табысына бағытталған тенденция және оның нәтижесі - құрметтердің азайтуы мен өндірістік жылдамдығының артуы.

Сапалы басылу қоймасын басқару механизмдері

Қысқарту процесінде өнімдердің сапасын алу үшін басын қалай тағайындау керемет. Ол қысқарту процесінде материалдарды зияндан сақтайды, сонымен қатар ұзынша және толықтық үшін маңызды екенін ескере отырып. Сенсорлар мен программаларды пайдаланатын құрметті басын басқару механизмдері дефекттер санын өте қарапайым төмендетуге мүмкіндік береді. Албеттесі, осы жүйелерді пайдаланушылар үшін және олардың ойындарының тізімін көру үшін, соңғы статистика бойынша көптеген ойындарда дефекттер санынан шақырлы төмен шығу көрсетілген. Бұл басын қалай тағайындауға қарағанда, адамгерлердің қателерін қалпына келтіруге көмектеседі және әрекеттерді тез өзгертуге мүмкіндік береді, осылайша саптастық басқарудың маңызды қосымшасы болып табылады.

CNC алюминий қиын жобалау арнайысымен интеграция

Бүгінгі шаршы тіркесу құралдары ең көп CNC алюминий терезелер қиындау машинасымен тікелей байланыстыру үшін дамытылуда - бұл шаршы тіркесу және терезе қиындау станцияларымен бірге қолданылатын, сонымен қатар сабақтағы жауап беру және жылдамдыққа мүмкіндік береді. Барлығын біріктіргенде, ол процестер қарапайым болады және қателер кеміреді, осылайша жеңілдетілген производство жылдамдығы артады. Мисалы, интегралды әдіс уашық жасау және әуелмек құрылғыларында кездесетін және дәлдік пен қызметкерлікке ықпал етеді. Осы қажеттіліктерді орнату арқылы, осы салалар қиындау және тіркесу операцияларын бір-бірімен орындау қабілеті бар құралдар үшін пияздың дамуын қосымша ықпал етуге көмектеседі, барлығы біріктірілген шешім, салалардың талаптарына сәйкес келеді.

Кеңес беруші технологиялармен сабақты оптимизациялау

Сапалылықты қамтамасыз ету үшін зерттеу сенсорлары

Өзікті сенсорлер өндірістегі сапалын тексеру процесін ауыстыру арқылы, крип сапасын және қателерді онлайн режимінде мониторлауда. Емістердің жағдайы түсінделі бір түрде тексеріледі және айырмашылықтар анықталады, сонымен қате продукцияларды минималаштыру үшін тез қамтамасыз ету жол дейін болады, соңғы продукт сапасы жақсы болады. Бұл өзік сенсорлердің дамуы мен аналитика платформаларына қосылуы олардың қызметкерлігіне қосымша болады. Өндірушілер превентивті техника қызметтерін пайдалану арқылы машиналардың іске қосылмауын алдын алу үшін қажетті әрекеттерді алып, планланған жоқ іске қосылмауларды және неожидан техникалық қызметтерге қатысты траттарды минималаштырады.

Автоматтық алюминий қырғызушыларда энергиясын сақтау өрнекі

Автоматтық алюминий қиындыру машиналарының энергиясына тәуелсіз қасиеттері бизнеслерде ұран мен бюджетке қарағанда сақтау стандарттарын өзгертіп жатады. Энергиясына тәуелсіз болғандықтан, олар энергию артықча сақтайды және эксплуатация құрал-жабдықтарын және кешенгі әсерді төмендетеді. Салықтағы ұсыныстарға сәйкес, энергиясына тәуелсіз дизайндарды қолдану 20% энергиясын сақтауға мүмкіндік береді, бұл ефективділігін дәлелдейді. Мүшеуле, ұранға бағытталған мақсаттар бұл өзгерістерге бағыт берген және дүниежүздегі қоршаған қорытындылармен бірлеседі. Бұл өзінде өндіріс ефективділігі емес, соңғы нұсқада қоршаған қорытындыларға қарағанда сондай-ақ пайдалы моделді қамтамасыз етеді.

Өндірістік секторлар арасында қолданбалар

Бұрышты тазарту машиналарымен біріктірілген бет қалпына келтіру үшін

Қабырғаларды қуып жату процесінде, өзгеше бет жобасы маңызды, көбінесе зейтунлы қолданбаларда, мұнда дәлдік және сенімділік ең маңызды. Күршілерді қуып жату машиналарымен беттерді тазарту машиналарымен біріктірсек, бұл бізге өндірістік қызметкерлікті қажетті деңгейге арттырады және продукттың сенімділігін қамтамасыз етеді. Бұл интеграция қабырғалардың тез өзгертілуін және қуып жатқан продукттердің негізгі сапасын қамтамасыз етеді.

Мысалы, алюминий құрылыс санайысы осы машиналарды бірлескен пайдаланғанда көпшілік отбасынан қаланың төменшігін жеткізді. Бір негізгі деректердің бірі – бұл әдісті қолданатын санайыларда материалдық отбасы 30% дейін азайтады, бұл нығайлылық пен ұрандықтың жүйелілігін көрсетеді. Бұл бірлескен әдіс не ең өте нығайлылықты арттырады, не сонымен қатар, бүгінгі күндерде іздейтін санайылар үшін ұрандық өндірістік техникаға сай.

Алуминий профиль жіберу системаларымен синергия

Алюминий профиль жібек жүйелері, кримп машиналарымен синхрондасқанда, шығыс сызықтарының өзгеше мәндерін арттырады. Бұл екі операция бірге қолданылатында, мүмкіндіктерге сай алюминийден жасалған құрылыс элементтердің өнімдерін жобалау процесінде шығыс арттыруға көмектеседі. Бұл стратегия қолданылса, шығыс арттыру нәтижелері табиғатта 25%-тен астам болуы мүмкін.

Бір ақпараттық уақыт ішінде, қасиеттер және пазар тенденциялары ешқандай жүйелер өндіріс сатыларына қалай кіреді, бұл негізгі фактор. Машиналарды секторларға қарағандағы қажеттілерге сайлау мүмкіндігі оларға толық қызмет көрсету потенциалын береді және өндірістің қабілетін жоюға көмектеседі. Егер сectors дамидырса, қияу/баспа интеграция спектрындағы кеңейтуге бағытталған өткені, модерн өндірістік жолдардың белгісі ретінде қалыптастыруға болады, маңызды өндірістік қабілет пен продукттың ұзақ өмір сүруіне бағытталған.

Санаттық Кримп Шешімдерінде Келешек Тенденциалары

AI-басқарылатын процестерді оптимизациялау

Искусственный интеллектті кримп операцияларына қолдану, осы саладағы операциялық еңбек берушілікті жетілдіру мүшеінде көп негізгі қадам болып табылады. ҚЖТ университетінің зерттеушілері су және шошка су системаларының энергия мен су сапарын азайту үшін AI-оптимизацияланған басқару әдісін дамытты. Кеңес етілген машинелік оқыту әдістері AI оптимизациясындағы системаларды оптимизациалау қарым-қатынасында қалайтын нәтижелерге ие болды. Сондықтан машиналар реальдық уақытта деректен ойына бастайды, ондағы алғашқы адамдық қосымша жоқ екенінде ұқсас түрде қуатты өзгертулер жасайды. Осылайша, орта әдістерге қарағанда, производительностьтің значительдікке жететін жаңа мүмкіндіктері басталады. Мисалы, біздер әлеуметтік өнеркәсібінде пайдаланылатын ИИ-ның пайдаларынан тиімділік көріп жүріп, Siemens компаниясының өнеркәсібінің қызмет жасау уақытын азайту және продукттың сапасын жақсырақ ету арқылы пайдалануда. Кримп технологиясына ИИ-ның қарым-қатынасы, іске асырылатын кримп машиналарының жұмыс тәсілдерін өзгертеді, оның қызметін жақсырақ етіп, тиімділікке жетуге мүмкіндік береді.

Бахытты дизайндар үшін көп мақсатты фабрикация

Модульді дизайнерлік тәсімдерге ауыстыру құралдарды баспа машиналарында жылдам өзгертіп, сабақтың сценарийлерін қайта анықтайды. Бұл модульді баспа жүйелерінің кеңістігі компанияларға жаңа саналу шарттарына сәйкес жылдам қатынасты қамтиды. Мысалы: Модульді машиналар өзгерту қажеттілігіне сәйкес қолайлы реттеумен басқа проекtlерге сәйкес келуге дейін. Кейбір компаниялар модульді дизайнерлік пайдалану арқылы қуындау уақытын азайтады және гибкестікті арттырады деп табылды. Пазар анализіне сәйкес, модульді машиналардың іздемей-жоғары саналу қажеттігіне сәйкес ешқандай индустриялық орталықта қажет болатын гибкі/әмиян производство үшін көбірек танымал болуы күтіледі.