The Impact of 12000r/min Spindle Speed on Aluminum Machining Performance

Understanding the Significance of 12000r/min Spindle Speed in CNC Routing

Setting the spindle speed around 12000 revolutions per minute works best when machining aluminum profiles because it strikes a good balance between cutting fast enough to get things done while still keeping temperatures under control. Standard CNC routers typically struggle with heat accumulation during long runs, which can cause problems like warping in those delicate thin-walled window frames we see so often. Some tests indicate that when working with aluminum grade 7075 specifically, running at 12000 instead of the slower 9000 rpm setting actually boosts metal removal rates by about 23 percent. That kind of improvement makes all the difference for shops doing large volume production work where every minute counts.

How High-Speed Spindle Motors Enhance Precision in Soft Metal Processing

Because aluminum melts at such a low temperature, proper chip removal becomes absolutely critical during machining operations. That's why many shops rely on high speed spindles these days, which can maintain very tight tool paths around 0.2mm stepover or better. This makes it possible to machine those intricate details in parts like wiring channels and locking mechanisms without getting stuck with built up edges or gummy residue problems. When running at speeds around 12,000 revolutions per minute, the lower radial forces significantly cut down on tool bending issues. Most manufacturers find this allows them to hold tolerances within about plus or minus 0.05mm, something that matters a lot when making doors and windows that need to seal properly against weather elements.

Comparison of Spindle Speeds: 12000r/min vs. Standard 8000–9000r/min for Aluminum

| Parameter | 12000r/min | 8000–9000r/min | Advantage |

|---|---|---|---|

| Surface Roughness | 0.8–1.2µm | 1.6–2.0µm | 40% improvement |

| Tool Life | 85–100 hrs | 60–75 hrs | +28% longevity |

| Cycle Time | 22 min | 31 min | 30% faster |

Data source: International Journal of Advanced Manufacturing Technology, 2021

Technical Advantages of High-Speed Spindles in Minimizing Tool Wear During Aluminum Milling

At 12000r/min, rapid chip evacuation keeps cutting temperatures within an optimal range (85–110°C), reducing built-up edge on carbide tools by 62% compared to lower speeds. This thermal stability significantly extends tool life and ensures consistent surface finishes across thousands of machining cycles, minimizing unplanned downtime and maintenance costs.

Precision and Surface Quality in Aluminum Profile Machining with High-Speed Copy Routers

Achieving high precision machining in window and door frame components

High-speed copy routers deliver ±0.02mm accuracy, meeting the stringent dimensional requirements of window and door frame manufacturing. This level of precision is critical when machining intricate features such as water drainage channels and hardware mounting points, where deviations beyond 0.1mm can compromise structural integrity and weather sealing performance.

Tolerance control when milling lock holes, water slots, and wiring grooves in aluminum profiles

With real-time speed compensation and stable spindle dynamics, modern copy routers maintain ±0.05mm consistency throughout batch production. The combination of 12000r/min operation and reduced cutting forces minimizes thermal distortion during slotting, ensuring accurate fitment for locks, drainage systems, and electrical components.

Toolpath stability and surface finish quality at 12000r/min

Elevated spindle speeds reduce harmonic vibrations by 62% compared to 8000r/min systems, resulting in surface roughness values (Ra) below 0.8µm—eliminating the need for secondary polishing. This vibration damping supports smooth toolpaths for sliding hardware surfaces, enhancing both functionality and aesthetics while reducing post-processing time.

Case study: Dimensional accuracy improvements using 12000r/min spindle speed

A 2023 industry analysis documented a 40% reduction in dimensional errors after manufacturers adopted 12000r/min copy routers. Improved groove depth consistency (±0.1mm across 10,000 units) and enhanced threaded hole concentricity (±0.03mm) directly contributed to lower rejection rates on assembly lines, demonstrating measurable gains in process reliability.

Productivity and Efficiency Gains in Industrial Aluminum CNC Routing

Increased Efficiency Through Faster Material Removal Rates at 12000r/min

Operating at 12000r/min enables 18–22% faster material removal than 8000r/min spindles, accelerating key processes such as milling, grooving, and drilling in window and door profile fabrication. By maintaining optimal chip load and minimizing dwell time, these high-speed systems boost throughput without sacrificing tool longevity.

Reducing Cycle Times in Mass Production of Aluminum Profiles

In production environments processing over 500 aluminum profiles daily, each unit saves 3.8–4.2 minutes at 12000r/min. This translates to 42–48 recovered productive hours per month. The efficiency gain stems from fewer spindle acceleration/deceleration cycles and optimized toolpath algorithms that reduce non-cutting movements.

Data Insight: Productivity Increase of Up to 35% With Optimized Spindle Speed

A controlled study across 12 industrial workshops revealed:

| Spindle Speed | Units/Hour | Tool Change Frequency |

|---|---|---|

| 9000r/min | 38 | Every 6.2 hours |

| 12000r/min | 51 | Every 5.8 hours |

The 34.2% increase in output demonstrates how higher RPMs reduce cutting force per revolution, effectively offsetting increased tool wear frequency with greater overall productivity.

Energy Consumption Analysis: Balancing Speed and Power Efficiency

Although 12000r/min operations draw 18–22% more instantaneous power than 8000r/min setups, intelligent torque management and variable-frequency drives optimize energy use. Shorter cycle times reduce total kWh per kilogram of material processed by 9–12%, achieving comparable or better energy efficiency in continuous production runs.

Key Selection Criteria for Copy Routers in Aluminum Profile Applications

Evaluating CNC Router Aluminum Processing Capabilities for Industrial Use

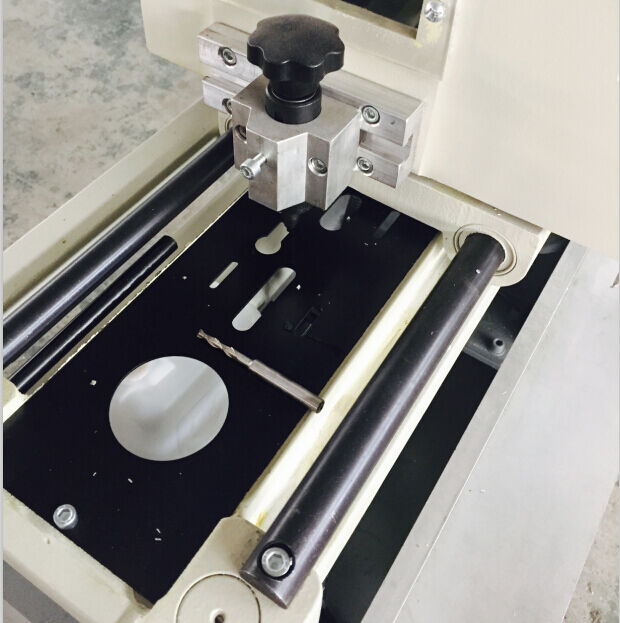

When working with aluminum profiles, it's best to go for copy routers that have at least 2.2 kW of spindle power and can spin up to around 12,000 rpm. These specs are needed for tougher jobs such as cutting lock holes or making wiring channels. For industrial settings, look for machines that maintain position within about 0.1 mm repeatedly. This kind of precision matters a lot when manufacturing window frames and doors consistently. Machines equipped with adaptive controls that tweak feed speeds according to how thick the material is actually cut down on waste materials by roughly 15-20% during those mixed batch runs where different parts get produced together.

Importance of Adjustable Speed Spindles for Versatile Profiling Tasks

Digitally controlled spindles allow seamless transitions between aluminum alloys. A 12,000r/min spindle maintains optimal chip load when switching from harder 6061-T6 structural profiles (300–400 HB) to softer 3003 cladding materials. This adaptability prevents tool deflection in thin sections and enables 35% faster slot milling compared to fixed-speed machines.

Vibration Damping and Thermal Management in High-Speed Aluminum Machining

Premium routers address high-speed challenges through dual strategies:

- Active vibration control: Polymer-concrete bases and linear guide damping systems reduce harmonic oscillations by 62% at 12,000r/min

- Thermal stability: Liquid-cooled spindles combined with chassis airflow designs maintain operating temperatures below 45°C during extended shifts, extending bearing life by 2.3× compared to passive cooling

Future Trends in High-Speed Copy Routers for Aluminum Window and Door Processing

Integration of Smart Controls in Next-Generation Aluminum Router Machines

Next-generation copy routers feature IoT-enabled smart controls that dynamically adjust feed rates (300–600 mm/sec) and spindle torque based on real-time profile thickness data. These systems cut setup time by 40–60% compared to manual configurations and support remote monitoring via cloud-connected interfaces, enabling firmware updates and troubleshooting without interrupting production.

Predictive Maintenance and Spindle Health Monitoring in High-Speed Routers

Vibration sensors work alongside thermal imaging to keep an eye on spindle condition even at high speeds around 12000 revolutions per minute. When it comes to machines equipped with predictive maintenance features, they tend to last about 30 percent longer before needing replacement, plus factories see roughly half fewer unexpected shutdowns compared to traditional setups. The system sends out warnings whenever bearings get hotter than 65 degrees Celsius or vibrations go beyond 5 micrometers these are basically warning signs that something might be going wrong with how stable the machining process remains. Research from industry reports indicates that implementing this kind of monitoring saves workshop owners approximately 18 thousand euros each year just on repairs alone for shops of moderate size.

Emerging Trends in Automation for Aluminum Profile Cutting

Modern automated router cells bring together six axis robotic arms and visual guidance systems, resulting in about 98.7% consistent parts during curtain wall manufacturing. These setups typically feature dual pallet tables along with automatic tool switches that keep operations running around the clock. The software side has also improved dramatically, with artificial intelligence programs cutting down on wasted materials by roughly 22% across various architectural applications. Add in those high speed 12,000 rpm spindles and some smart flipping mechanisms for workpieces, and we're seeing cycle times drop by nearly 35% when tackling those tricky three dimensional grooves in metal components.

FAQ

What is the significance of using a 12000r/min spindle speed for CNC machining?

The 12000r/min spindle speed is crucial for balancing fast cutting rates with controlled temperatures, enhancing material removal rates, precision, and productivity in industrial scenarios.

How does high-speed machining benefit aluminum processing?

The high-speed spindle helps maintain tight tool paths, facilitates chip removal, reduces tool bending, and holds tolerances within ±0.05mm during machining operations.

Does higher spindle speed affect energy consumption?

While 12000r/min uses more instantaneous power than lower speeds, it ultimately optimizes energy usage with shorter cycle times and intelligent power management, leading to overall efficiency.

What factors should be considered when selecting a CNC router for aluminum machining?

Key factors include spindle power, ability to maintain position precision, adjustable speeds, and features that offer adaptive control over varied material types for reduced waste and improved efficiency.

Table of Contents

-

The Impact of 12000r/min Spindle Speed on Aluminum Machining Performance

- Understanding the Significance of 12000r/min Spindle Speed in CNC Routing

- How High-Speed Spindle Motors Enhance Precision in Soft Metal Processing

- Comparison of Spindle Speeds: 12000r/min vs. Standard 8000–9000r/min for Aluminum

- Technical Advantages of High-Speed Spindles in Minimizing Tool Wear During Aluminum Milling

-

Precision and Surface Quality in Aluminum Profile Machining with High-Speed Copy Routers

- Achieving high precision machining in window and door frame components

- Tolerance control when milling lock holes, water slots, and wiring grooves in aluminum profiles

- Toolpath stability and surface finish quality at 12000r/min

- Case study: Dimensional accuracy improvements using 12000r/min spindle speed

- Productivity and Efficiency Gains in Industrial Aluminum CNC Routing

- Key Selection Criteria for Copy Routers in Aluminum Profile Applications

- Future Trends in High-Speed Copy Routers for Aluminum Window and Door Processing

- FAQ