Understanding Warranty Coverage for Corner Crimping Machines

Manufacturer Warranties for Industrial Machinery: What to Expect

Most reliable suppliers of corner crimping machines come with warranty coverage for important parts such as hydraulics, electrical controls, and those crimping dies that tend to wear out over time. According to a recent 2025 industry analysis by major manufacturers in the field, around 89 percent of business customers actually look for suppliers who can guarantee at least a year's worth of full component protection. What do these standard warranty packages generally cover? They usually promise free replacements when parts fail, access to technical experts for problem solving, plus regular software and firmware updates to keep control systems running smoothly. Some companies even throw in extended service options for an extra fee.

Typical Warranty Duration and Its Impact on Operational Continuity

Industrial crimping equipment typically comes with warranties lasting anywhere from one to three years, and around two thirds of manufacturers actually offer different levels of coverage these days (Ponemon Institute 2024). When companies go for the extended three-year option instead of just the standard one-year plan, they see a pretty significant drop in downtime problems somewhere around forty-two percent based on what operational reliability research shows. Most suppliers make it clear that their warranty will only stay valid if certain conditions are met. They want proof that regular maintenance was done according to schedule, that only approved tools were used during crimping operations, and that all calibration records have been properly maintained and documented throughout.

Warranty Coverage Details (Parts, Labor, Duration): A Breakdown

Coverage typically follows an 80/20 pattern:

| Component | Coverage Duration | Labor Included? |

|---|---|---|

| Hydraulic cylinders | 3 years | Yes |

| Control units | 2 years | No |

| Wearable dies | 6 months | No |

While reputable suppliers typically exclude consumables like seals and gaskets, 92% cover circuit boards and servo motors for the full warranty period. Always verify if freight costs or onsite labor require separate service contracts.

Key Components Covered Under Reputable Corner Crimping Machine Warranties

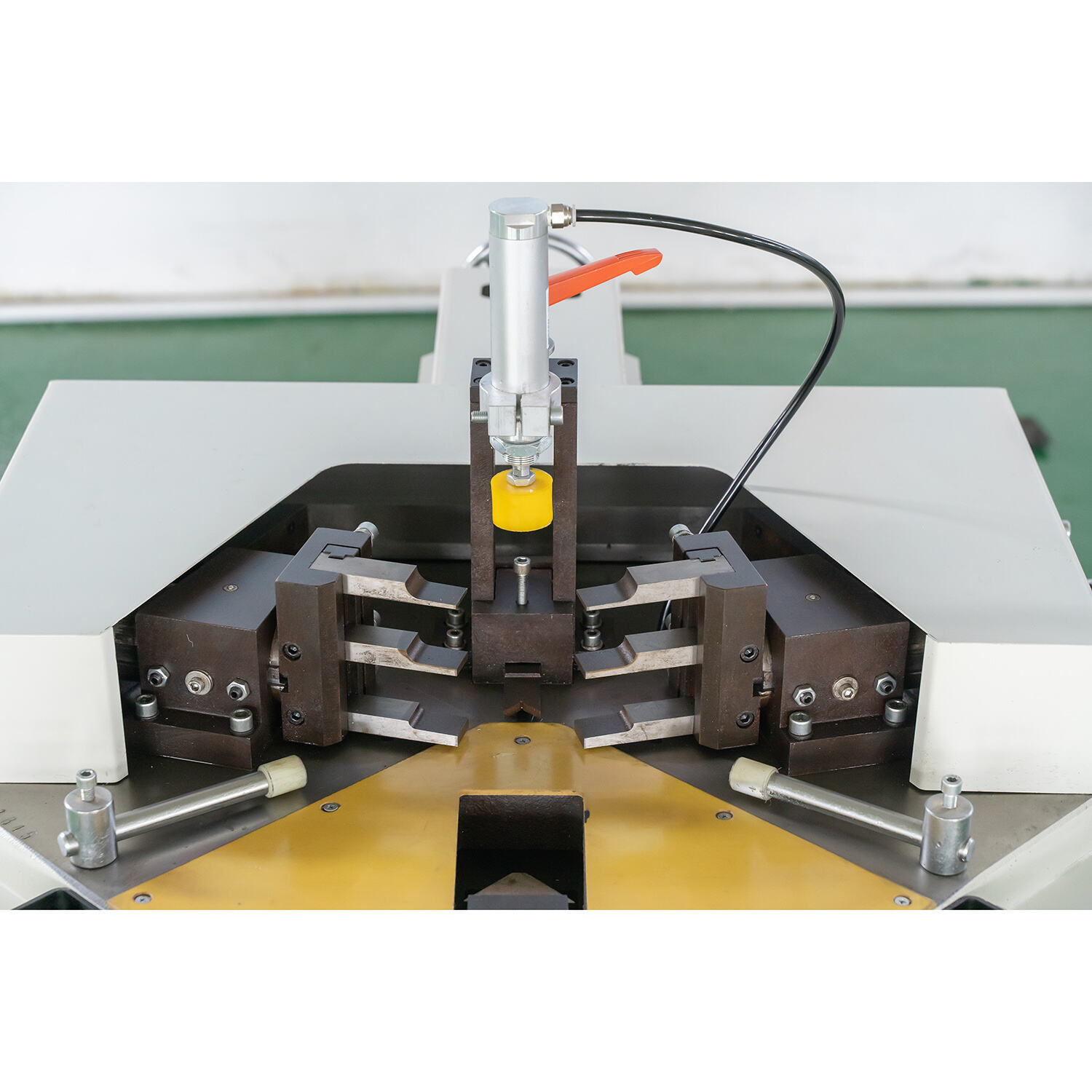

Protection for Hydraulic Systems and Crimping Dies

Most warranties these days include hydraulic power units and crimping dies since they tend to take a real beating during operation. According to recent industry reports, about 38 percent of downtime problems in wire processing machines come from issues with hydraulic systems, so having coverage makes good business sense. Good warranty programs typically handle common problems like fluid leaks, pressure system failures, and those pesky die misalignments that happen when there are flaws in the materials being processed. Operators who stick to the manufacturer's recommended tools generally find better results too, though this isn't always mentioned upfront in warranty terms.

Electrical Control Units and Sensor Reliability Guarantees

Today's advanced machinery depends heavily on PLCs and position sensors to achieve those tiny fractions of millimeter accuracy we all need. Good manufacturers offer solid warranties covering their control systems against things like short circuits, software glitches, and gradual calibration shifts over roughly three years or so. The sensor setups that monitor crimp forces usually range between 5 to 50 kilonewtons, and these really matter in production environments. When something goes wrong with them, it can send scrap rates skyrocketing as much as nearly 20% in connector manufacturing situations. That kind of waste adds up fast on the factory floor.

Adherence to Manufacturer Recommendations for Component Longevity

Getting warranty coverage usually requires sticking to scheduled maintenance checks and going with parts certified by original equipment manufacturers. A lot of warranty claims get rejected simply because someone used non-certified dies or missed regular lubrication steps. Most suppliers actually send out detailed maintenance guides that list exactly what kind of lubricants work best for ball screws, specify proper torque settings for electrical connections, and outline how many operating cycles different bushing components can handle before replacement. Following these guidelines keeps the warranty valid, sure, but there's another benefit nobody talks about much machines tend to last anywhere from four to seven extra years when properly maintained in factory environments. Shop managers know this well since extended equipment life means fewer capital expenditures down the road.

Common Warranty Exclusions: What Reputable Suppliers Typically Don’t Cover

Damage from improper use or uncertified crimping tools

Reputable suppliers universally exclude damage caused by improper operation or non-OEM accessories. Industry studies reveal 62% of hydraulic system failures stem from using non-compliant dies or exceeding pressure specifications. Most agreements state that operating beyond rated cycle speeds voids actuator coverage, using third-party dies without ISO 9001 certification nullifies die plate protection, and modifications to electrical interfaces terminate sensor warranties.

Wear and tear vs. manufacturing defects: Supplier distinctions

Manufacturers clearly differentiate between expected degradation and true defects. A typical 12-month warranty covers:

| Covered | Not Covered |

|---|---|

| Hydraulic seals | Premature cracking <6 months |

| Compression wear after 10,000 cycles | Guide rollers |

| Bearing seizure (manufacturing flaw) | Surface polishing from material friction |

| Control panels | Software glitches |

| Moisture damage from workshop conditions |

This ensures genuine defects are addressed while routine replacements remain the operator's responsibility.

Consequences of skipping maintenance and calibration of crimping tools

Warranty validation hinges on documented maintenance compliance. One manufacturer reported 81% of denied claims involved missing calibration records. Critical oversights include failure to replace wear plates after 50,000 crimps, using expired calibration certificates, and ignoring quarterly lubrication protocols. Operators must maintain logs showing adherence to all OEM-prescribed intervals to preserve coverage.

How to File a Warranty Claim with Corner Crimping Machine Suppliers

Step-by-step guide to initiating a warranty claim

Initiate a claim promptly by reviewing your supplier's terms—88% require notification within 14 days of defect discovery. Follow this protocol:

- Submit written notice via the supplier's designated portal or email

- Include machine serial numbers, purchase invoices, and timestamps

- Attach photographic or video evidence of the malfunction

- Specify affected components such as hydraulic rams or crimping dies

Documentation required and response time expectations

Suppliers typically require original purchase invoices, maintenance logs proving service compliance, and failure reports detailing pre-breakdown conditions. Industry-leading case management systems reduce resolution times by 40% through automated verification. Most reputable suppliers provide initial assessments within 7 business days, though complex hydraulic claims may take up to 14.

Supplier support during claim resolution and minimizing downtime

Top suppliers deploy field technicians within 72 hours for critical failures. During repairs:

- 73% offer temporary replacement machines

- 92% provide remote diagnostics via IoT-enabled control panels

- All certified suppliers maintain emergency parts inventories

Pro Tip: Schedule non-urgent claims during planned maintenance windows. Suppliers often prioritize clients who coordinate claims with production schedules.

Maximizing Machine Longevity: Training, Support, and Maintenance Beyond the Warranty

Onsite and Remote Training Programs from Corner Crimping Machine Suppliers

Proper training reduces misuse by 67% and boosts efficiency by up to 30%. Leading suppliers offer blended learning combining onsite workshops, virtual reality simulations for diagnosing hydraulic faults, and certification exams. These programs align with ISO 9001 standards and directly reduce premature wear from operational errors.

Importance of Using Certified Crimping Tools and Systems

Non-certified tooling accelerates degradation by up to 4× compared to OEM-approved alternatives. Verified crimping dies maintain ±0.005mm tolerance for 12–18 months, versus 3–6 months for generic versions, ensuring consistent production quality.

Maintenance and Calibration of Crimping Tools as Warranty Prerequisites

85% of manufacturers require quarterly maintenance logs and annual calibration certificates to honor extended warranties. Key checks include hydraulic fluid purity, laser micrometer verification of die alignment, and firmware updates. Overlooking these steps results in voided coverage in 92% of cases.

How Ongoing Technical Support Reduces Downtime and Extends Machine Life

24/7 technical hotlines resolve 78% of issues within 90 minutes. Remote diagnostics now predict 60% of hydraulic failures 48+ hours in advance using real-time pressure analysis, predictive wear modeling, and automated spare parts ordering. This proactive approach extends average machine lifespan from 7 to 12 years in high-use environments.

FAQ: Corner Crimping Machine Warranties

What is typically covered under a corner crimping machine warranty?

Most warranties cover hydraulic systems, electrical controls, and crimping dies. They promise free replacements, technical expert access, and software updates for smooth operation.

How long do warranties for corner crimping machines last?

Warranties typically range from one to three years, with extended options potentially reducing downtime significantly.

What documents are necessary for filing a warranty claim?

Suppliers require original purchase invoices, maintenance logs, and failure reports detailing pre-breakdown conditions.

Are consumables covered under warranty?

No, consumables like seals and gaskets are typically not covered.

Why is adherence to maintenance protocols important?

Documented maintenance is crucial for warranty validation and can extend machine life by several years.