Driving Automation and Operational Efficiency in Assembly Lines

In today's manufacturing world, screw fastening machines are really changing how things get done, meeting those tough requirements for both precision work and quick production times. Instead of relying on people who might make mistakes when tightening screws by hand, these machines do the job consistently every single time. They can hit torque specs within about 0.1 Nm most of the time actually around 99.8% according to that report from 2024 on automation efficiency. What makes these systems so powerful is how they connect with PLCs and those smart industrial internet of things platforms. This connection lets everything work together smoothly across the factory floor with conveyor belts moving parts along, automated feeders supplying components, and quality checks happening right where needed.

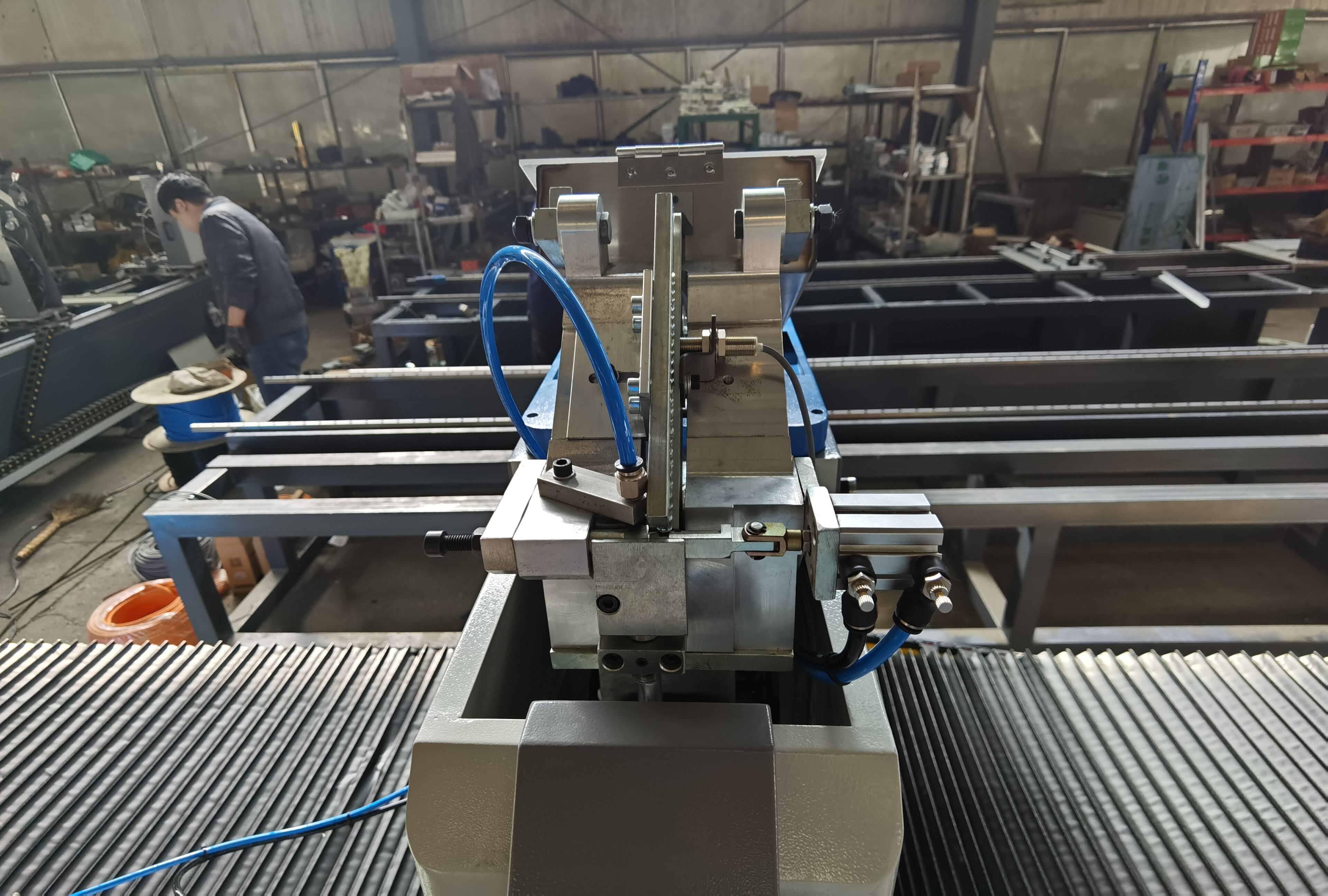

The Role of Screw Fastening Machines in Advancing Assembly Line Automation

Automated screwdrivers complete tasks 3.2x faster than manual operators while maintaining 98.5% first-pass yield rates. This eliminates bottlenecks in electronics assembly, where a single smartphone line requires 120+ screws with micron-level positioning.

Integration with Industrial Automation Systems for Synchronized Production

Modern systems sync with MES platforms using OPC UA protocols, allowing real-time adjustments. For example, if a sensor detects panel warping, the machine recalibrates insertion depth within 0.8 seconds—flexibility manual teams cannot match.

Impact on Operational Efficiency in High-Volume Manufacturing

Automotive plants using these systems report 18% shorter cycle times and 63% fewer warranty claims from loose components. High-volume consumer electronics manufacturers achieve 24/7 production with less than 0.5% downtime through predictive maintenance algorithms.

Case Study: Automotive Assembly Lines Leveraging Screw Fastening Automation

A leading EV manufacturer reduced battery pack assembly errors by 79% after deploying vision-guided screw fastening robots. The system handles 11 screw types across 4 vehicle platforms, switching configurations in 22 seconds—compared to 45 minutes previously required for manual retooling.

Ensuring Precision and Quality Assurance in Fastening Processes

How Screw Fastening Machines Ensure Consistent Torque and Alignment

Today's screw fastening machines cut down on inconsistencies by using programmable torque settings that match what different materials need and how threads are shaped. These machines have closed loop feedback systems that tweak the turning power as they go along, so they stay within those ISO 5393:2013 standards for repeatable results, usually staying within plus or minus 2% accuracy on torque measurements. When something goes wrong, like if screws get cross threaded or not aligned properly, special error detection software stops everything right away before bad parts can move further along the production line. One big car parts maker actually saw their problems with faulty fasteners drop by around 34 percent once they started using these kinds of machines in their factory.

Real-Time Inspection and Data Logging for Quality Traceability

When it comes to fastening operations, integrated sensors now collect detailed information like torque curves, axial forces, and how much something rotates during assembly. The system adds time stamps and identifies which workstation did what, making these records pretty much impossible to alter while still meeting those strict IATF 16949 requirements that automotive companies live by. Factories find all this data incredibly useful. They can spot when torque starts drifting out of spec long before things go beyond acceptable limits. For aerospace customers, the system generates those required AS9102 FAIR reports automatically, saving tons of paperwork headaches. And let's not forget the bottom line impact: studies show plants using this tech cut down on manual inspections by around two thirds in complex electronics manufacturing setups where multiple products are assembled simultaneously.

Reduction in Human Error and Product Defects

When it comes to screw placement, automation brings consistency that no human hand can match. Just look at what happened when appliance makers started using robots for this task back in 2023. Warranty claims dropped by almost half because those pesky loose fasteners stopped being such a problem. The difference really matters in sensitive areas like medical devices though. Imaging equipment with improperly tightened screws isn't just a technical glitch it's a potential disaster waiting to happen. One manufacturer had to shell out over seven hundred forty thousand dollars when their MRI machines needed recalls due to these issues according to MedTech Quality Journal last year.

Reducing Labor Costs and Optimizing Workforce Roles

Screw fastening machines as a solution for labor cost reduction

When companies automate those tedious manual screwdriving tasks, they save money on labor costs in two main ways: fewer people needed for the job and way less errors happening along the way. A single automated system can do what used to take several workers, plus it applies consistent torque every time instead of relying on human hands that might vary slightly between screws. The savings are pretty substantial too, around 25 to maybe even 40 percent cut from direct labor bills when production volumes get really high. And this addresses one of the biggest monthly expenses most factories face. What's interesting is how these machines also free up resources so companies don't need as much overtime pay or spend so much on training new staff. This works especially well in places making automotive electronics where products typically have more than 90 connection points that all need just the right amount of tightening force applied in sequence.

Shifting workforce roles toward supervision and maintenance

When screw fastening gets automated for those repetitive jobs, techs start moving into better roles like coordinating predictive maintenance work and checking product quality during production runs. The shift helps workers learn new skills, makes their jobs more satisfying overall, and boosts how well operations run day to day. Instead of spending all day tightening screws manually, staff members are looking at ways to get machines running smoother. This kind of teamwork between people and machines actually leads to better products coming off the line and means fewer defects that need fixing later on.

Integration with Robotics and Industry 4.0 Smart Manufacturing

Synergy between screw fastening machines and robotics in automated assembly

Modern screw fastening machines integrate seamlessly with robotic arms, achieving positional accuracy of ±0.1mm. This enables fastening in hard-to-reach areas—essential for automotive battery tray installations and aerospace composite panel assemblies. Leading automotive plants report 40% faster cycle times when combining collaborative robots with electric screwdrivers.

Role in smart manufacturing and the Industry 4.0 revolution

As foundational IoT devices, screw fastening machines feed real-time torque data (5–50 Nm range) to Manufacturing Execution Systems (MES), enabling self-optimizing production lines. According to the 2025 Industrial Robotics Market Report, 73% of smart factories using automated fastening tools reduced torque-related defects by 60% through cloud-based analytics.

Data-driven customization and adaptive fastening parameters

Advanced models process over 1,200 data points per minute—from screw thread engagement depth to material surface hardness—automatically adjusting torque curves mid-process. This adaptability supports rapid product changeovers, with some modular systems reconfiguring tooling in under eight minutes for mixed-model assembly.

Trend: Predictive maintenance in automated screw fastening systems

Vibration sensors and motor current analysis predict gearbox failures 300–500 operating hours in advance. Manufacturers using these systems report 89% fewer unplanned downtime events compared to conventional setups. Cloud-connected models can even auto-order replacement parts when wear thresholds exceed ISO 5393:2017 standards.

Flexible and Scalable Modular Solutions for Diverse Industries

Modular automation enabling rapid reconfiguration of screw fastening systems

The modular nature of screw fastening machines comes from their plug-and-play components which really boost production flexibility. These machines can be reconfigured in just a few hours rather than taking days as was common before. The ability to adapt quickly matters a lot in industries such as consumer electronics manufacturing and home appliance assembly plants. Standardized connections between different modules make things run smoother on factory floors. A recent look at industrial design trends for 2025 suggests that these kinds of adaptable systems cut down on equipment downtime expenses by around 30 percent while speeding up when companies launch new products. For manufacturers looking to grow, they don't need to replace whole production lines every time they want something changed. Just slotting in fresh modules works wonders, keeping production rates steady and helping factories stay competitive against rivals who might not have made this kind of investment yet.

Custom assembly machines for specialized automotive and aerospace applications

In precision manufacturing fields, there's a growing need for specialized screw fastening systems when dealing with complicated parts such as engine blocks or turbine assemblies. The best systems can hold torque levels within about plus or minus 0.10 Newton meters consistently, even when working with unique materials developed specifically for certain applications. These custom made machines actually change how they tighten bolts depending on what kind of tolerance the part requires. According to recent findings from the Aerospace Assembly Journal published last year, this kind of smart adjustment has cut down rejected components in the aerospace industry by roughly twenty two percent. When we talk about preventing catastrophic failures in places where vibrations are constant companions, these customized automated solutions make all the difference. Plus they help manufacturers stay within those strict quality certifications that regulators demand so much these days.

Scalability of flexible automation systems across production lines

The modular platform design makes scaling operations much easier when moving from small test runs to full scale manufacturing. Companies often start with just one workstation setup for their specialty products before expanding outwards throughout their factory space. The step-by-step expansion model cuts down on upfront investment costs by around 40 percent when compared to traditional all-in-one systems. Looking at actual production numbers, there's a clear pattern where costs drop steadily as more stations get added. Each additional parallel station brings down what each unit actually costs to produce, all while keeping quality control tight within about plus or minus five microns. What really stands out is how these setups make better use of available factory floor area and allow businesses to quickly boost production capacity whenever they launch something new to market.

FAQ

What is the main benefit of using screw fastening machines in manufacturing?

Using screw fastening machines in manufacturing provides consistent precision and reduces human errors, thus enhancing product quality and operational efficiency.

How do screw fastening machines integrate with modern industrial systems?

Screw fastening machines integrate with modern industrial systems by connecting to PLCs and IoT platforms, allowing synchronized and flexible production processes.

Can screw fastening machines help in reducing labor costs?

Yes, screw fastening machines can significantly reduce labor costs by automating repetitive tasks and decreasing the need for manual intervention.

How do screw fastening machines contribute to Industry 4.0 initiatives?

As IoT devices, these machines provide real-time data to Manufacturing Execution Systems and support self-optimizing production lines as part of Industry 4.0 initiatives.

Are modular screw fastening solutions adaptable for different industries?

Yes, the modular design allows fast reconfiguration, making them suitable for diverse industries like electronics, automotive, and aerospace manufacturing.

Table of Contents

- Driving Automation and Operational Efficiency in Assembly Lines

- Ensuring Precision and Quality Assurance in Fastening Processes

- Reducing Labor Costs and Optimizing Workforce Roles

- Integration with Robotics and Industry 4.0 Smart Manufacturing

- Flexible and Scalable Modular Solutions for Diverse Industries

-

FAQ

- What is the main benefit of using screw fastening machines in manufacturing?

- How do screw fastening machines integrate with modern industrial systems?

- Can screw fastening machines help in reducing labor costs?

- How do screw fastening machines contribute to Industry 4.0 initiatives?

- Are modular screw fastening solutions adaptable for different industries?