Essential Machinery for Aluminum Window Production

Aluminum Profile Cutting Machines: Precision and Speed

Aluminum profile cutting machines play a really important role in making windows from aluminum, giving manufacturers incredible accuracy and cutting down on wasted materials. These machines cut profiles so precisely that every single window frame comes out exactly as designed, which means fewer mistakes happen during production and more efficient use of raw materials. Industry reports suggest that when companies upgrade to newer cutting tech, they often see their production speeds jump around 30 percent while saving about 20% on labor expenses too. The boost in both accuracy and how fast things get done translates into better overall productivity and real money saved at the end of the month. For window makers trying to stay ahead in today's tough market, having good aluminum profile cutting equipment isn't just helpful it's pretty much necessary if they want to keep producing high quality products without breaking the bank.

CNC Aluminum Cutting Machines: Automated Accuracy

CNC aluminum cutting machines have changed how things get made thanks to their automation capabilities and super accurate cuts. When manufacturers use this tech, they end up with parts that are consistently cut right, which means fewer mistakes overall. Some research shows these machines can actually speed up operations by around 25 percent or so, plus they cut down on those pesky human errors we all know happen sometimes. For businesses needing top notch quality without wasting time or materials, CNC tech is a game changer. Window component makers especially benefit from this stuff because the precision just makes everything work better together. Factories can now produce reliable batches faster than ever before, scaling production as needed without compromising on quality standards.

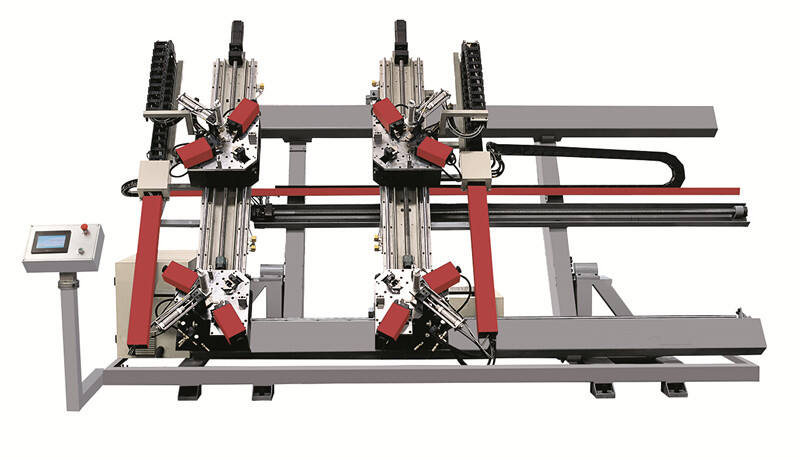

PVC Welding Machines: Seamless Joint Fabrication

PVC welding machines play a really important role when it comes to making those seamless joints that make aluminum windows last longer. These joints look great too, but they do more than just look good. They actually improve how well the windows keep heat out and stop water from getting through. People who work with these machines report that windows made this way tend to need less fixing over time and just plain last better. Plus, companies save money because the whole process goes faster. No need for extra sealants or anything like that, which cuts down on waste and makes production run smoother. Getting these welding machines into the workshop represents a real step forward for anyone wanting to build windows that stand up to wear and tear while keeping manufacturing expenses under control.

Aluminum Bending Machines: Shaping Flexibility

Aluminum bending machines bring something special to the table when it comes to creating custom windows. These machines let designers work on all sorts of different looks and functions that customers want. Many shop owners have told us about how their equipment handles pretty much any design spec thrown at it. That's why they're so valuable for jobs needing those unusual or complicated window shapes. When a machine can actually bend and form aluminum profiles just right, it opens up whole new worlds of design options. Architects get to deliver exactly what clients need instead of settling for standard solutions. The fact that these machines keep evolving means window makers stay ahead of changing trends in the market place while still meeting tough specifications from building codes and energy efficiency standards.

Role of CNC Technology in Reducing Human Error

Computer Numerical Control (CNC) tech really helps cut down on mistakes made by people, which means better quality products come out of factories. These machines are built to be super precise, so they eliminate all those little variations that happen when someone does things by hand. Manual work tends to produce inconsistent results, and that leads to bad parts and production holdups. When companies automate complicated operations, each piece gets cut exactly right according to the blueprints. Some industry reports show error rates went down around half after businesses started using CNC systems. This makes sense because when parts fit together properly from the start, there's less waste and rework needed throughout the manufacturing process.

Automated Welding Solutions for Consistent Quality

In aluminum window manufacturing, automated welding has become essential for maintaining quality throughout production runs. These machines follow set programs to create consistent welds time after time, something regular workers just can't match consistently over long shifts. What really matters is how they repeat the same process precisely every single time, which means stronger frames that last longer without issues down the road. Take Deceuninck North America as an example company that switched to these automated systems several years back. Since making the change, they've noticed fewer defects coming off the assembly line and faster turnaround times on orders, all while keeping those tight tolerances required for proper installation in buildings across different climates.

Robotic Systems for High-Volume Production

Robots really crank up productivity when dealing with large scale manufacturing, making things run smoother and cutting down on what companies spend for workers. The tech just works faster and more accurately than old school methods ever could, which means factories can push their production numbers higher and get more done overall. Take Erdman Automation Corp as an example they saw their output jump quite a bit after bringing robots into the mix, saving around 30 percent on costs too. What this shows is that companies serious about hitting tough production targets need look no further than automation if they want to keep those labor bills under control without sacrificing quality.

Implementing Corner Cleaning Machines for Smoother Finishes

Corner cleaning machines are essential for getting those quality finishes when manufacturing aluminum windows. These devices smooth out edges and get rid of those annoying rough corners that can mar the look of finished products. Manufacturers know this well because they see customer expectations rise every day. When workers talk about their experiences, many point to how much better looking and consistent their window products become after implementing corner cleaning tech. Beyond just looks, these machines actually streamline production processes while cutting down on defects caused by poor corner work. Most shops now consider corner cleaners a must have rather than an optional upgrade in today's competitive manufacturing landscape.

Material Handling Systems to Minimize Downtime

![]2W0`Y}RE02DWLAZHU1PVB4.jpg](https://shopcdnpro.grainajz.com/category/15405/2551/b8bcba27201d4179b49e87012f39db09/%5D2W0%60Y%7DRE02DWLAZHU1PVB4.jpg)

Good material handling systems really make a difference when it comes to keeping operations running smoothly and cutting down on those frustrating production stoppages. When materials get placed exactly where they need to be and move through the factory floor without bottlenecks, workers spend less time waiting around and factories crank out products faster. Industry reports show that factories investing in updated handling equipment often save between 15-30% on processing times while getting better results from their machines. For most manufacturers, this means fewer employees needed for repetitive tasks and generally higher quality products coming off the assembly line. Of course, not every company sees immediate returns, but over time these systems tend to create workflows that just keep going without hiccups, which translates into实实在在 more goods produced each day across various manufacturing sectors.

Lean Manufacturing Principles in Window Assembly

The application of lean manufacturing concepts has really taken off in window assembly shops across the country. When applied properly, these methods cut down on wasted materials and time, which means better quality windows get produced faster without breaking the bank. Most window factories implementing lean approaches start by looking at every step of the process through fresh eyes, asking questions like Why do we do it this way? or Can this be done differently? Toyota was one of the first companies to truly master these techniques back in the 70s, and their success stories still inspire many manufacturers today. For smaller window producers trying to keep up with bigger competitors, going lean isn't just about saving money either it often leads to stronger customer relationships because orders arrive on time and defects drop significantly. Many shop owners report that once they commit to continuous improvement, even small changes add up over time.

Routine Calibration of Cutting and Bending Tools

Keeping cutting and bending tools properly calibrated matters a lot when it comes to getting accurate results and good quality work. If we skip regular checks, tiny mistakes can snowball into big problems down the line, messing up everything from product quality to how consistent things look across batches. Most shops stick to calibrating their equipment somewhere between once a month and every other month, though some machines need more frequent attention based on how hard they're worked and what specs they have. When companies ignore these maintenance tasks, they end up shortening the life of their expensive machinery while increasing chances of all sorts of production issues. That means more money spent fixing things and less time actually making products. Regular calibration isn't just about following rules it's about keeping operations running smoothly day after day.

Lubrication Schedules for PVC Welding Equipment

Sticking to lubrication schedules makes all the difference in keeping PVC welding gear running smoothly. When parts get properly greased, they don't rub against each other so much, which means less wear and tear on the components. That translates to fewer breakdowns down the line and machines lasting longer before needing replacement. Most manufacturers actually design their equipment with specific lubrication requirements in mind, so it pays to check those specs carefully. The right kind of oil matters too – some welders work better with certain types of lubricants depending on how hot they run during operation. Making lubrication part of regular maintenance isn't just good practice for machine health, it saves money over time by avoiding costly repairs and downtime. Smart shop managers know this simple step keeps production moving without unexpected interruptions.

Diagnosing Wear in CNC Drive Components

Knowing how to spot wear in CNC drive parts is really important if factories want to keep running smoothly. When technicians check regularly with monitoring equipment, they catch problems early on things like strange sounds coming from the machine or odd vibrations that nobody should be feeling during normal operation. This kind of proactive approach works wonders. Some shops report cutting down breakdowns by almost half just by sticking to regular maintenance routines. Take predictive maintenance systems for instance. These technologies actually warn operators about possible trouble spots long before anything serious happens. Keeping those finely tuned components in good shape means better reliability across the board. The end result? Fewer production stoppages and consistently accurate machining results throughout the shop floor.

Certification Programs for CNC Machine Operation

CNC machine operator certification really makes a difference when it comes to improving skills and keeping everyone safe on the shop floor. When workers go through these training programs, they actually learn how machines work properly, which cuts down on mistakes and prevents accidents. The numbers back this up too. Shops that invest in certified operators tend to see way fewer incidents compared to places where nobody has proper training. Some factories report around 30% fewer accidents after getting their staff certified because people just know what they're doing better. Beyond safety improvements, trained operators generally get more done without breaking things. Looking at it from a business standpoint, spending money on certification isn't just about compliance anymore. It's becoming clear that having skilled workers who understand their equipment leads to both safer conditions and better bottom line results over time.

Ergonomic Practices in Aluminum Profile Handling

Good ergonomics matters a lot when working with aluminum profiles because nobody wants to deal with workplace injuries while moving around those heavy, awkward materials all day long. Workers need proper support through things like specialized lifting equipment and better work station setups that take pressure off their backs and shoulders. Most industry pros will tell anyone willing to listen about keeping good posture during lifts, investing in quality lifting aids, and making sure everyone gets proper training before handling these materials. These simple steps go a long way toward preventing those nagging muscle and joint problems that plague so many manufacturing jobs. Companies that actually implement real ergonomic improvements see fewer accidents happening on site, which means happier employees overall and less hassle dealing with OSHA requirements down the road.

Emergency Protocols for High-Speed Machinery

Emergency plans for fast moving machines are absolutely necessary if we want to keep workers safe and stop accidents from happening. These machines run so quickly and have so many parts that they create real dangers which can cause major injuries when things go wrong. Good emergency plans should outline exactly what needs doing when something breaks down or an employee gets into trouble. Looking at actual incidents shows how sticking to proper procedures stops disasters before they happen, leading to much better safety results. Take one factory that put strong emergency rules in place. They saw accident numbers drop significantly while employees felt much more confident about operating the equipment. Getting these safety measures right isn't just good practice it's essential for any workplace that wants both safety and productivity.

Table of Contents

-

Essential Machinery for Aluminum Window Production

- Aluminum Profile Cutting Machines: Precision and Speed

- CNC Aluminum Cutting Machines: Automated Accuracy

- PVC Welding Machines: Seamless Joint Fabrication

- Aluminum Bending Machines: Shaping Flexibility

- Role of CNC Technology in Reducing Human Error

- Automated Welding Solutions for Consistent Quality

- Robotic Systems for High-Volume Production

- Implementing Corner Cleaning Machines for Smoother Finishes

- Material Handling Systems to Minimize Downtime

- Lean Manufacturing Principles in Window Assembly

- Routine Calibration of Cutting and Bending Tools

- Lubrication Schedules for PVC Welding Equipment

- Diagnosing Wear in CNC Drive Components

- Certification Programs for CNC Machine Operation

- Ergonomic Practices in Aluminum Profile Handling

- Emergency Protocols for High-Speed Machinery