Dəqiqlik və Kəsmə Doğruyu Standartları

Bıçağın Keyfiyyətinin Rolu Alüminium Profilin Kəsilməsində

Alüminium profillərin kəsilməsinə gəldikdə, bıçağın keyfiyyəti təmiz, dəqiq nəticələr əldə etmək üçün bütün fərqi yaradır. Daha yaxşı bıçaqlar sadəcə tez köhnəlmir və kəsilən materialda daha hamar kənarlar buraxır, yəni iş daimi fasilələr olmadan daha sürətli aparılır. Karbidlə örtülmüş bıçaqları və ya yüksək sürətli poladdan hazırlanmış bıçaqları götürün, məsələn, bunlar dəyişdirilməyə ehtiyac duymazdan əvvəl əhəmiyyətli dərəcədə daha uzun müddət dayanır və müntəzəm mağaza əməliyyatları zamanı daha az baxım tələb olunur. Sənaye insayderləri qeyd edirlər ki, yaxşı keyfiyyətli bıçaqlara əvvəlcədən pul xərcləmək əslində uzun müddətdə pula qənaət edir, çünki daha az qırıntı materialı israf edilir və hazır məhsullar da daha yaxşı görünür. Üstəlik maşınlar gözlənilməz qəzalar olmadan daha uzun müddət işləyir. Alüminium profil işlərində yüksək səviyyəli standartları qorumağa ciddi yanaşan mağazalar üçün bıçaq seçimi və ümumi məhsuldarlıq arasındakı bu əlaqə sadəcə olaraq göz ardı edilə bilməz.

CNC Metal Kesim Maşınları üçün Kalibrasiya Sistemləri

CNC metal kəsmə dəzgahlarının düzgün kalibrlənməsi işləri dəqiq saxlamaq üçün çox vacibdir, xüsusən də kütləvi istehsal parametrlərində tam sürətlə işləyərkən. Bu kəsiklərin nə qədər dəqiq başa çatması, kiminsə bunu əl ilə etməsindən və ya sistemin avtomatik idarə etməsinə icazə verməsindən çox asılıdır. Bu günlərdə tam avtomatlaşdırılmış quraşdırmalardan tutmuş köhnə moda əl ilə düzəlişlərə qədər hər cür kalibrləmə variantları var və onlar həqiqətən kəsmənin nə qədər yaxşı işləməsində fərq yaradır. Mağazalar müntəzəm kalibrləmə prosedurlarına sadiq qaldıqda, komponentləri daha az tez köhnəlirkən, ümumilikdə daha yaxşı maşın performansını görürlər. Maşınlar da daha uzun müddət kəskin qalır, bu da dəyişdirmə ilə daha az baş ağrısı deməkdir. Kalibrləmə oyununu güclü saxlayan mağazalar gündən-günə daha təmiz kəsildiyini bildirir, üstəlik onların avadanlıqları adi yoxlamaları atlayanlardan daha uzun illər xidmət edir. Alt xətt? Düzgün kalibrləmə istehsal olunan şey və zamanla nə qədər pulun bankda qalması baxımından böyük vaxt ödəyir.

Material Uyğunluq və Kəsmə Qabiliyyəti

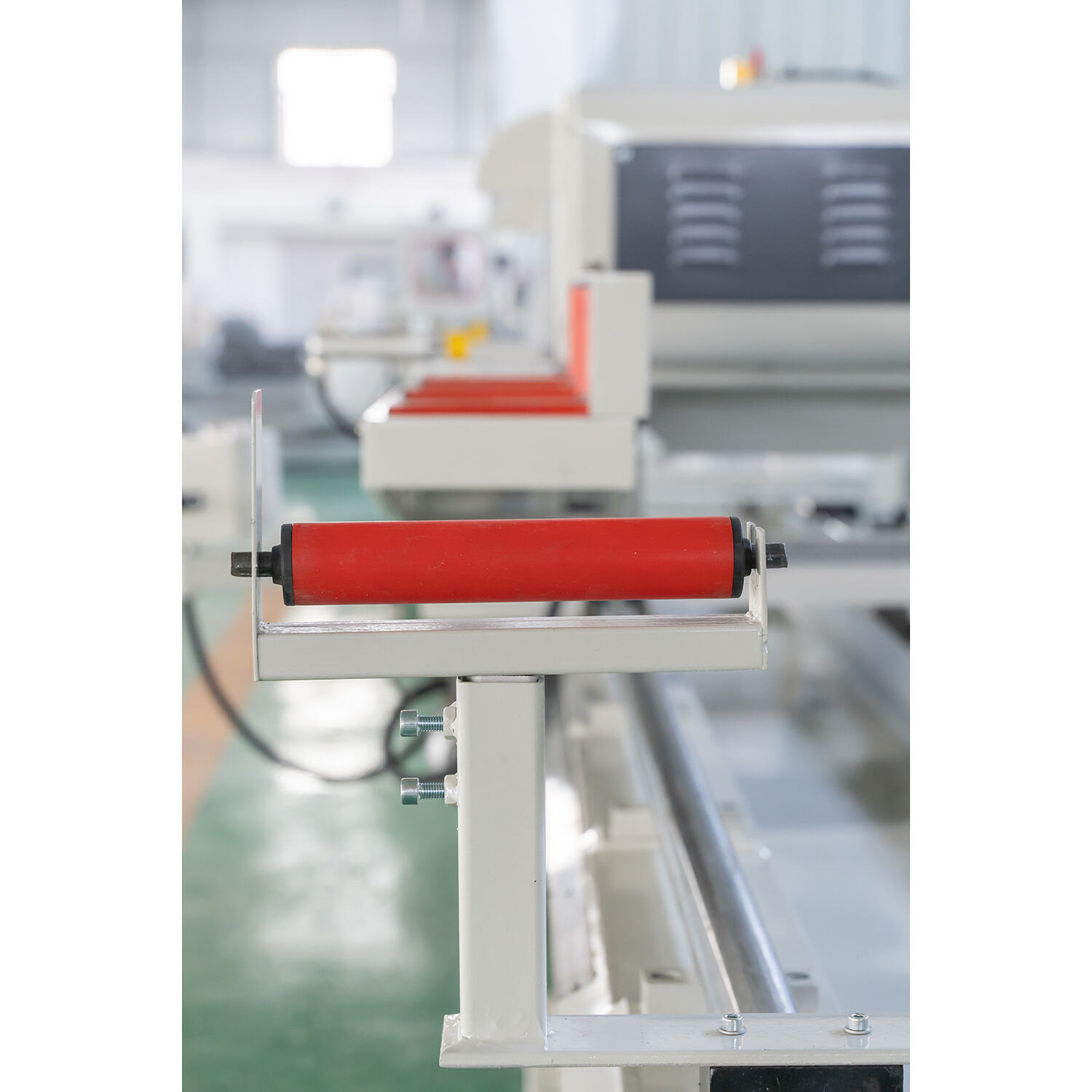

Müxtəlif Alüminium Profillərin İdarə Edilməsi Ekstruziya avadanlıqları

CNC maşınları əsas formalardan tutmuş istehsal sərhədlərini aşan xüsusi dizaynlara qədər bütün növ alüminium profilləri idarə etmək üçün real universallığa ehtiyac duyur. Bu maşınlarla işləyərkən, müxtəlif xüsusiyyətlərə uyğunlaşma müxtəlif işlərdə düzgün kəsmə nəticələrini təmin edir. Material uyğunluğu da çox vacibdir, xüsusən də ekstruziya proseslərində istifadə olunan müxtəlif ərintilərlə. Bu uyğunluq həm məhsulun nə qədər istehsal olunduğuna (məhsuldarlıq dərəcələrinə), həm də istehsal üçün nə qədər vaxt lazım olduğuna təsir göstərir. İstehsalçılar öz seçimlərini nəzərdən keçirərək, yaxşı performans göstərərkən müxtəlif materiallarla işləməyi bacaran CNC sistemlərinə diqqət yetirməlidirlər. Son zamanlar sənayedə baş verənlərə nəzər salsaq, daha yaxşı material uyğunluğu istehsal zamanı baş ağrısının daha az olması və ümumilikdə səmərəliliyin artırılması deməkdir. Alüminium profillərin getdikcə daha mürəkkəb və rəngarəng olması ilə, əsas düzəlişlər etmədən materiallar arasında keçid etmək rəqabət qabiliyyətini saxlamağa çalışan əksər istehsalçılar üçün praktiki olaraq məcburi hala gəldi.

Sayt Metal Profil Maşın İnteqrasiya Nəzarəti

Daha yaxşı əməliyyat səmərəliliyini istəyiriksə, təbəqə metal profil maşınları cari iş axınlarına yaxşı uyğunlaşmalıdır. Bu maşınlar artıq sexdə baş verənlərlə rəvan inteqrasiya etdikdə istehsal daha sürətli və təmiz olur, bu da saatda daha çox hissənin çıxması deməkdir. Fərqli işlər üçün avadanlıq seçərkən hər bir maşının nə edə biləcəyini dəqiq bilmək çox vacibdir. Nəhayət, lazer kəsmə maşını ştamplama əməliyyatları üçün də işləməyəcək. Maşın və tapşırıq arasında düzgün uyğunluq əldə etmək, zamanla pula qənaət etməklə yanaşı, məhsuldarlıqda real qazanc əldə edir. Zavod statistikası göstərir ki, düzgün inteqrasiya çox vaxt hər şeyin birlikdə işləməsindən asılı olaraq hasilatı təxminən 15-20% artırır. Bu maşınları harada yerləşdirmək və birləşdirmək barədə ağıllı planlaşdırma gündəlik əməliyyatlarda böyük fərq yaradır. Bunu ciddi qəbul edən istehsalçılar daha az darboğaz görürlər və bir prosesin digərinə başlamazdan əvvəl bitməsini gözləmək üçün daha az vaxt itirirlər.

Avtomatlaşdırma və CNC Texnologiyalarının Entqra edilməsi

CNC Metall Kəsmə Maşını Proqramlaşdırma Fleksibiliteti

CNC proqramlaşdırmasına daxil edilmiş çeviklik, avadanlığı daim yenidən konfiqurasiya etmədən mürəkkəb metal kəsiklər üzərində işləyərkən bütün fərqi yaradır. Uyğunlaşa bilən proqramlaşdırma ilə təchiz olunmuş maşınlar müxtəlif profil ölçüləri və formalarının geniş spektrini idarə edə bilər ki, bu da işlərin nə qədər sürətli yerinə yetirilməsini həqiqətən artırır. Əksər mağazalar gündəlik işlərində G kodu və M kodu kimi standart proqramlaşdırma dillərinə etibar edirlər. Bu kod sistemləri operatorlara kəsmə prosesləri üzərində möhkəm nəzarət imkanı verir və onlara istədikləri dəqiq nəticələri əldə etməyə imkan verir. Məsələn, detallı metal hissələrdə ixtisaslaşmış bir mağaza götürün. Daha çevik CNC proqramlaşdırmasına keçdikdə, quraşdırma vaxtı kəskin şəkildə azaldı və insanların istehsal işləri zamanı hər şeyi əl ilə düzəltməyə ehtiyacı daha az oldu. Alt xətt? İstehsalçılar nə qədər istehsal etdikləri və bu məhsulların bir çox istehsal dövründə nə qədər dəqiq olması ilə bağlı nəzərəçarpacaq təkmilləşdirmələr olduğunu bildirirlər.

Alüminium Guillotine Kesimi və Foil Şablon Kesim Üsulları

Alüminium gilyotin kəsmə ilə folqa kəsmə üsulunu müqayisə etmək, hər bir metodun nə qədər səmərəli olması və hansı iş növləri üçün ən yaxşı işlədiyi ilə bağlı böyük fərqləri aşkar edir. Gilyotin kəsicilər düz kəsikləri həqiqətən yaxşı idarə edən sürətli maşınlardır, bu da onları təbəqə metal kəsmə və ya panel kəsmə kimi işlər üçün əla edir. Qablaşdırma materiallarında gördüyümüz o dəbdəbəli loqolar və ya dekorativ naxışlar haqqında düşünün. Xərc tənliyi də fərqli görünür. Gilyotin quraşdırmaları hazırlamaq və istismar zamanı daha az material sərf etmək üçün az vaxt tələb olunur, buna görə şirkətlər orada pula qənaət edirlər. Lakin tibbi cihaz komponentləri və ya aerokosmik hissələrin yaradılması kimi dəqiqlik ən vacib olanda, folqa ilə kəsmə üçün əlavə xərclər buna dəyər. Əksər istehsalçılar sürətin vacib olduğu toplu sifarişlər üçün gilyotinlərdən istifadə edir, eyni zamanda folqa kəsicilərini hər bir ölçməni düzgün əldə etməyin tamamilə vacib olduğu niş tətbiqlər üçün saxlayır. Hər iki üsul arasında bu balansı əldə etmək mağazalara resursları lazımsız yerə sərf etmədən məhsullarını maksimum dərəcədə artırmağa kömək edir.

Təhlükəsizlik Xüsusiyyətləri və Operativ Effektivlik

Alüminium Kesici Piller Üçün Acil Dayanma Mekanizmləri

Təcili dayanma sistemi alüminium kəsərkən işçilərin təhlükəsizliyini təmin etmək üçün həqiqətən vacibdir. Əgər bir şey səhv olarsa, bu dayanacaqlar insanlara mişarı dərhal bağlamağa imkan verir ki, bu da qəza risklərini əhəmiyyətli dərəcədə azaldır. Əksər maşınlar təkan düyməsi və ya çəkmə şnur sistemləri ilə təchiz edilmişdir. Bu cihazlar quraşdırmadan əvvəl ciddi təhlükəsizlik testlərindən keçməlidirlər, buna görə də ən çox ehtiyac duyulduqda sürətli və etibarlı işləyirlər. Bəzi mağazalar hətta yüksək sürətli əməliyyatlar zamanı işçilərin mühafizəsi ilə bağlı əlavə ehtiyatlı olmaq üçün maşın çərçivəsi boyunca bir neçə dayanma nöqtəsi quraşdırırlar.

Əməyin mühafizəsi məlumatları göstərir ki, yaxşı fövqəladə dayandırma sistemləri olan maşınlar iş yerində qəzaları bir qədər azaldır. Keçən il nəşr olunan İş Təhlükəsizliyi Jurnalının son araşdırmalarına görə, bu təhlükəsizlik mexanizmlərini quraşdıran iş yerlərində qəza nisbətləri təxminən 30% azalır. Bu barədə düşünəndə həqiqətən məna kəsb edir. Emal əməliyyatları zamanı lazımi təhlükəsizlik funksiyalarının yerinə yetirilməsi artıq yalnız qaydalara riayət etməkdən ibarət deyil. Bu, əslində işçilərin təhlükəsizliyini təmin etməklə yanaşı, bütün iş mühitini iştirak edən hər kəs üçün daha təhlükəsiz edir.

Ən yüksək həcmli istehsal ortamlarında ergonomik dizayn

Ən çox məhsul ümumiyyətlə əsaslı istehsal ortamında, operatorun yorulmasını azaltmaq və hasilatı artırmaq üçün ergonomik dizayn çox vacibdir. Ayarlanabilən iş stantları və istifadəçi üçün asan interfeyslər kimi əsas elementləri daxil etməklə, texnika operatorun rahatlığını və effektivliyini böyük dərəcədə artırabilir. Bu tip dizaynlar, təkrarlanan işlərlə məşğul işçilərdəki fəzələyi azaltmaq üçün daha tabii pozisiya dəstəkləyir.

Tədqiqatlar bir çox işçinin erqonomika haqqında bildiklərini təsdiqləyir. Keçən il Applied Ergonomics Journal-da dərc edilən araşdırmaya görə, düzgün erqonomika ilə dizayn edilmiş maşınların iş yerində xəsarətləri təxminən 20% azaltdığı göstərilmişdir. İş yerləri erqonomikaya diqqət yetirdikdə, işçilər də öz işlərində daha xoşbəxt olurlar. Üstəlik, tez-tez məhsuldarlıq səviyyələrində nəzərəçarpacaq artım və hazır məhsullarda daha az qüsur var. Daha yaxşı dizayn edilmiş alətlər və avadanlıqlara pul xərcləyən şirkətlər adətən real nəticələr görürlər. İşçilər daha sağlam qalırlar, daha az xəstə gün keçirirlər və növbələrinin sonunda özlərini yorğun hiss etmədən və ya stress keçirmədən daha çox işlər görürlər. Bu dəyişikliklərdən əldə edilən uzunmüddətli qənaət adətən ilkin investisiya xərclərini xeyli üstələyir.