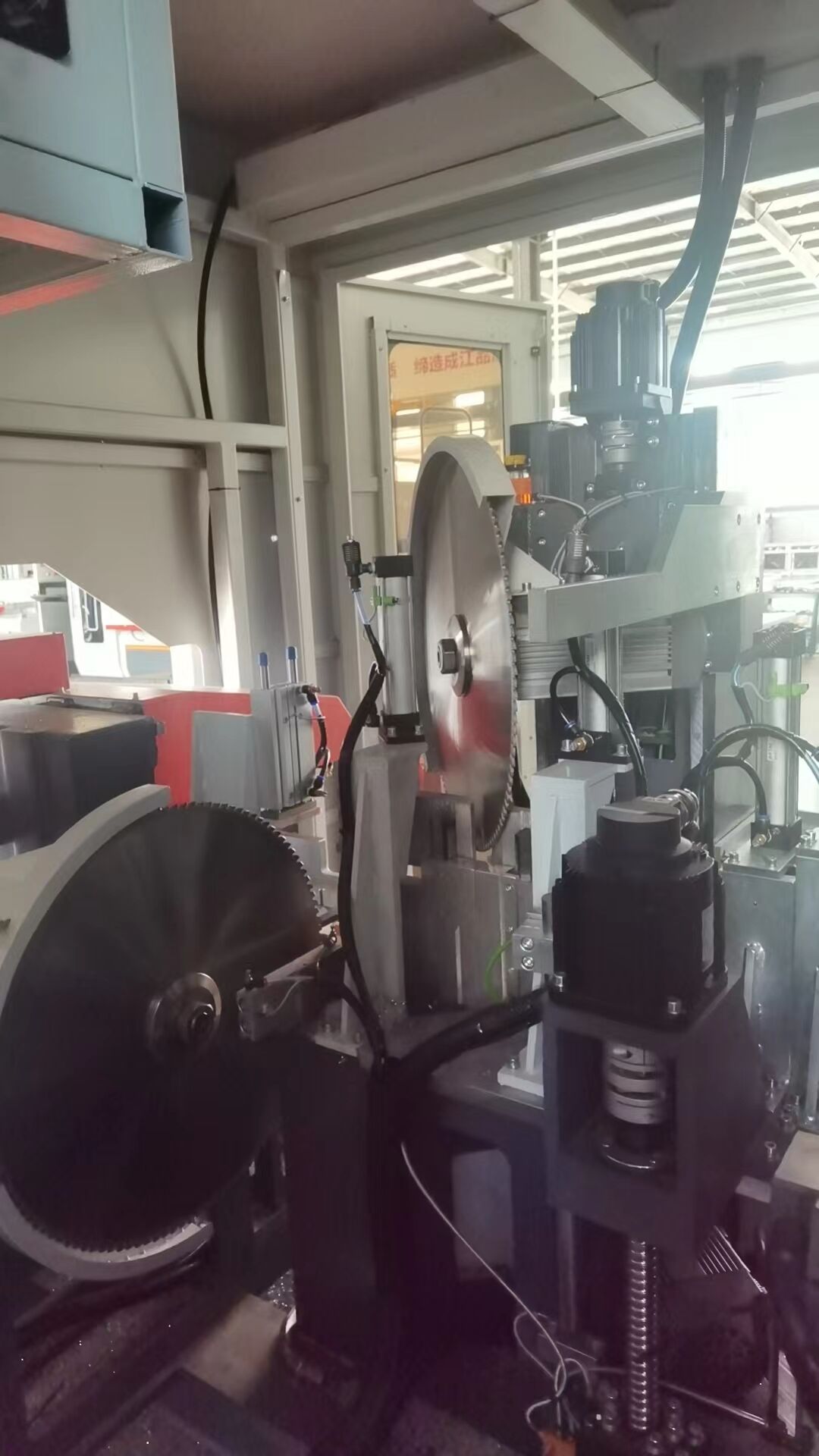

Automatic Aluminum Profiles CNC Cutting Milling Center for Window and Door Making Machinery

Aluminum profile laser cutting and engraving center enables efficient single-sided drilling and double-sided marking. Equipped with 3KW motor, servo feed, and intelligent laser system, it supports profiles from 360–6600mm with 150×150mm section. Delivers high precision: ±45°/90° cutting, 0.1mm length error, ≤0.10mm flatness. Automatically adjusts power and processing modes by wall thickness. Features fool-proof operation, automatic loading/unloading, and batch processing—no skilled labor or custom molds required.

Description

Parameter

Company Profile

FAQ

Jinan Truepro is a professional manufacturer based in Shandong, China, specializing in high-quality Insulating Glass Production Lines, Glass Cutting Machines, Glass Processing Machinery, Aluminum & UPVC Window Machines, and Profile Bending Equipment. Established in 2014, our company serves clients across Southeast Asia, Africa, North and South America, Europe, the Middle East, and Asia.

We guarantee product quality through strict pre-production sampling and thorough final inspections before shipment. With a dedicated team of 11–50 experienced professionals, we control every step from raw material selection to finished machine assembly, ensuring reliability and performance.

Our competitive edge lies in our strong R&D capability, comprehensive quality control, customizable solutions, and customer-centric services. We support flexible delivery terms (FOB, CIF), multiple payment options (T/T, L/C, PayPal, Escrow), and communicate fluently in English, Chinese, and German.

As a trusted supplier verified by SGS and backed by Trade Assurance, we ensure secure and timely transactions for customers worldwide.